Line Contacted Steel Wire Rope

Linear contact steel wire rope is a type of wire rope where all the wires in the strand are laid in one operation(in the same direction). The lay lengths of all the wire layers are equal and the wires of any two superimposed layers are parallel, resulting in linear contact. This design allows for even distribution of load and reduces wear and fatigue, making it suitable for applications requiring high strength and durability.

Overview

Linear contact steel wire rope and its strand

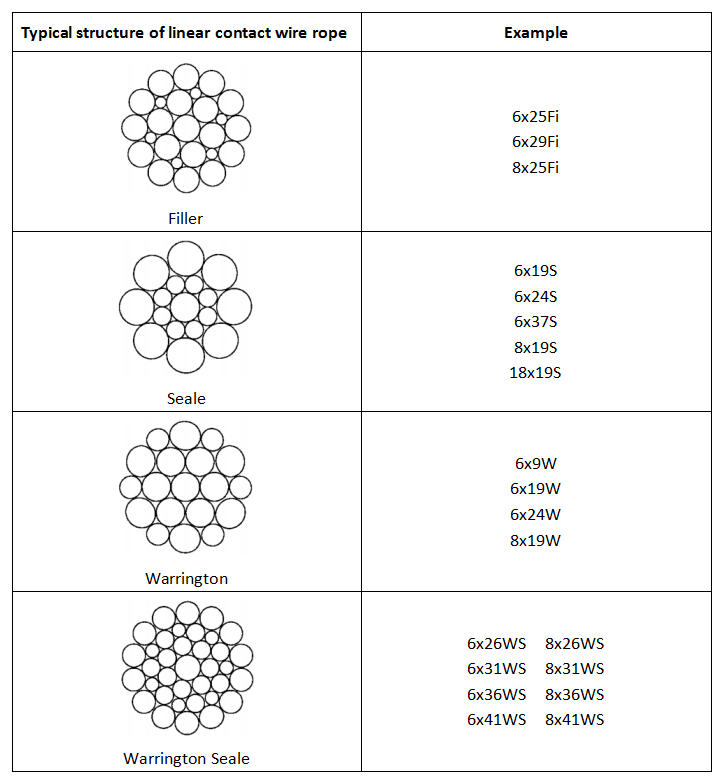

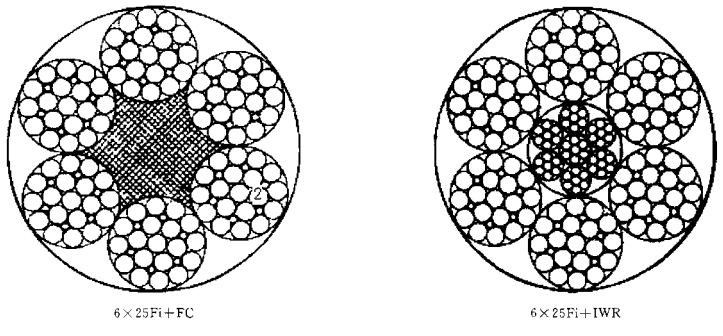

Filler(Fi):parallel lay strand construction having an outer layer containing twice the number of wires than the inner layer, with filler wires laid in the interstices between the layers. The filler wire is thin and the number of wires is the same as the inner wire. Structural formula: 1+N+N F +2N. e.g. 6x25Fi

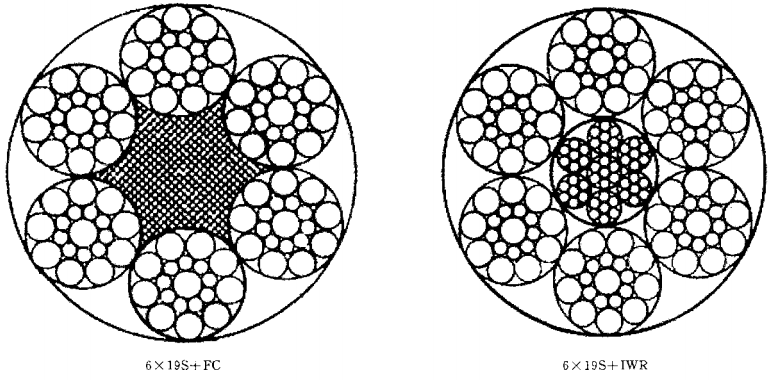

Seale(S): parallel lay strand construction with the same number of wires in both layers. Structural formula: 1+N+N. e.g. 6x19S

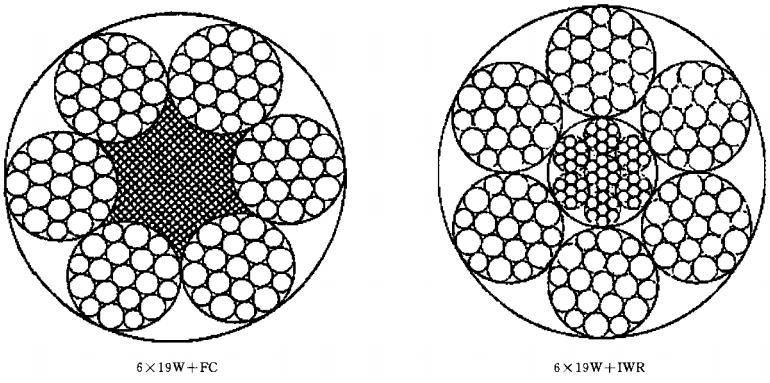

Warrington: parallel lay strand construction having an outer layer containing alternately large and small wires and twice the number of wires as the inner layer. Structural formula: 1+N+N/N. e.g. 6x19W

Combined parallel lay

Parallel lay strand construction having three or more layer laid in one operation and from a combination of strand types Warrington and Seale. A variety of composite line contact structures can be formed by two or three combinations of Warrington, Seale and filler (written with the center indicated outwards).

Linear contact (parallel lay) structure characteristics:

1. In a linear contact steel wire rope, the helical lines of all the steel wires are parallel to each other and do not intersect. The lay length of the wires in each layer is equal, but the lay angle of the wires is not equal.

2. Adjacent layer wires are embedded in the grooves of each other.

3. The diameters of the wires in each layer are not equal, but there is a certain proportional relationship. In use, the linear conatct steel wire rope can avoid deformation, internal wear, and secondary bending stress caused by point contact of the steel wires in the rope.

4. When the linear contact steel wire rope bears load, the contact stress between the wires is much smaller than that of the point contact steel wire rope. Therefore, the service life of the linear contact steel wire rope is generally 1 to 2 times longer than that of the point contact structure steel wire rope.

Application:

Line contacted steel wire rope can be widely usedto heat shift steel shat, shaft lifting, blast furnace hoisting, oil drilling, belt conveyor, cableway traction, cable cars, excavators, large cast cranes, cranes, loading and unloading ships. It has advantages of not easy to break wires, wear resistance, fatigue resistance, high pull breaking limit, and around 50% longer serve life.