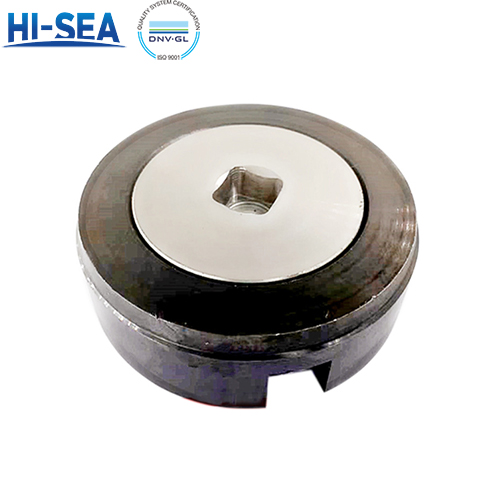

JIS F3005 Bottom Plug

JIS F3005 Bottom plug is a Marine device used for drainage and sealing. Under normal circumstances, the bottom plug is tightly connected to the bottom of the ship, ensuring a seal and effectively preventing water from entering the cabin. When there is water, the water at the bottom of the cabin can be discharged to prevent the water from causing damage to the ship, and the impact of the wet environment on the ship's equipment and cargo can be reduced.

Overview

How to test the performance index of ship bottom plug sealing material

1. Sealing performance test: Observe whether there is water leakage.

2. Corrosion resistance test: Simulate the corrosive environment such as seawater to check the corrosion of materials.

3. High and low temperature test: test the performance of the material under different temperature conditions.

4. Tensile strength test: Measure the tensile strength of the material.

5. Elasticity and flexibility test: Evaluate the elasticity and flexibility of the material.

6. Wear resistance test: test the wear resistance of the material.

7. Aging resistance test: Investigate the performance changes of the material in long-term use.

8. Hardness test: Determine the hardness of the material.

9. Chemical composition analysis: analysis of the chemical composition of the material.

10. Appearance inspection: Observe the surface quality of the material.

Note the following points when testing

1. Test strictly in accordance with relevant standards and methods.

2. Select the appropriate test equipment and instruments.

3. Accurately record and analyze the test results.

4. Calibrate and maintain the test equipment regularly.

By testing the performance index of Marine bottom plug sealing material, it can ensure that the material can meet the use requirements of the ship and ensure the safety and reliability of the ship.