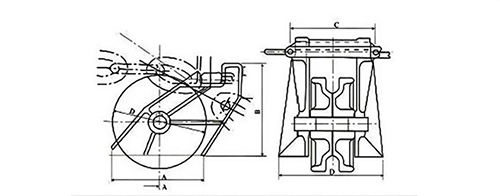

JIS F2033 Roller Bar Type Chain Stopper

Material: Typically made from high-strength steel for durability and corrosion resistance.

Design: Equipped with a roller bar mechanism to facilitate smooth operation and reduce wear on the chain.

Operation: The stopper can be engaged or disengaged easily, often using a manual lever or similar mechanism.

Safety: Designed to withstand high loads and provide secure holding of the anchor chain in various sea conditions.

Overview

Specifications:

Standards: Conforms to the Japanese Industrial Standards (JIS F2033), ensuring reliability and consistency in marine applications.

Sizes: Available in various sizes to accommodate different chain diameters typically used in marine settings.

Load Capacity: Engineered to handle significant loads, matching the tensile strength of the chains used on the vessel.

Installation: Can be installed on the deck or other designated areas of the ship where the anchor chain runs.

Certificate: ABS,CCS,LR,BV,NK etc.;

Applications:

Anchor Handling: Primarily used to secure the anchor chain when the anchor is stowed.

Marine Vessels: Suitable for use on various types of marine vessels, including cargo ships, tankers, and offshore platforms.

Maintenance:

Inspection: Regular inspections are required to ensure the stopper is free of rust and wear.

Lubrication: Periodic lubrication of the roller mechanism to maintain smooth operation.

Unit: mm

| Nominal Number | 73 | 78 | 84 | 90 | 95 | 102 | 107 | 114 | 122 | 132 |

| Anchor Chain Diameter | 70~73 | 76~78 | 81~84 | 87~90 | 92~95 | 97~102 | 105~107 | 111~114 | 117~122 | 127~132 |

| A | 730 | 780 | 840 | 900 | 950 | 1020 | 1070 | 1140 | 1220 | 1320 |

| B | 715 | 760 | 820 | 890 | 945 | 1005 | 1070 | 1140 | 1220 | 1315 |

| C | 700 | 730 | 780 | 840 | 880 | 940 | 990 | 1040 | 1100 | 1170 |

| D | 730 | 780 | 840 | 900 | 950 | 1020 | 1070 | 1140 | 1220 | 1320 |

| Weight (kg) | 1000 | 1180 | 1470 | 1780 | 2110 | 2380 | 2900 | 3440 | 4100 | 5080 |

| Note:the gross wight doesn’t include the weight of handle or counterweight. | ||||||||||