Is there anything to look for in a marine carpet?

Selecting a marine carpet requires careful attention to several critical factors beyond aesthetics. Due to the demanding shipboard environment—exposure to moisture, salt, stringent safety rules, and high traffic—the wrong choice can lead to premature wear, safety hazards, and non-compliance. Here are the key aspects you must look for.

Overview

The calculated dimensions of marine carpets not only involve the physical dimensional parameters of the carpet itself, such as width, length, thickness, etc., but also need to take into account the material of the carpet, flame retardant properties and other safety performance indicators to ensure that they meet the specific environmental and safety standards of the ship.

The size calculation of marine carpet is mainly based on the actual demand and the specific space of the cabin to determine. The carpets used in large cruise ships are marine carpets, due to the use of special places, mainly seawater, the environment is relatively humid, so the technical requirements of marine carpets are higher than general carpets.

Carpet cutting:

1. Accurately measure the size of the room, according to the size and shape of the space, cut the carpet according to the carpet cutting diagram, the length of each section of the carpet should be about 2cm longer than the room, the width of the carpet should be calculated by the size of the carpet edges after cutting out the carpet, and cut the edges of the pop-up line.

2. Pay attention to whether the carpet texture and laying direction is consistent. In the same room or section of each carpet pile direction should be matched with the same, the pile direction towards the backlit side of the laying, so as not to produce color differences.

3. When cutting carpets with patterns and stripes, the patterns and stripes must be aligned and matched at the seams.

4. When cutting the staircase carpet, there should be a certain margin of length so that it can be moved to the position of frequent wear and tear in the use of the carpet.

5. At the seams, first pop up the carpet cutting line, and then cut from the back of the carpet with hand-pushed cutter, the cut should be straight and neat so as to facilitate the splicing.

Key Factors to Consider

1. Safety and Compliance (Primary Consideration)

Flame Retardancy: Must meet the stringent flame retardancy standards of the International Maritime Organization (IMO) and classification societies (such as ABS, DNV). This is a mandatory requirement.

Smoke Toxicity: Low Smoke Low Toxicity (LSLT) performance is crucial in enclosed compartment fires.

2. Materials and Construction

Fiber Type: Synthetic fibers (such as nylon and polypropylene) are the preferred choice for marine applications due to their excellent mildew resistance, abrasion resistance, and easy cleaning properties. Explain the applicable areas for different materials.

Backing Material: Requires a waterproof and mildew-resistant rubber or PVC backing to prevent moisture penetration to the deck.

3. Environmental Adaptability

Mildew and Antibacterial Properties: Materials must be treated to inhibit the growth of mold and bacteria in humid environments.

Salt Spray and UV Resistance: Carpets suitable for open or semi-open areas must possess this property.

4. Performance and Durability

Abrasion Resistance Rating: Select the appropriate rating based on area traffic (e.g., corridors higher than guest rooms).

Stain Resistance and Ease of Cleaning: Consider styles with stain-resistant treatments for easy maintenance.

Dimensional Stability: The carpet should not shrink or deform due to humidity changes, affecting the seams.

5. Installation and Maintenance

Professional measurement, cutting (allowing for allowances), pile alignment, and pattern matching are key to ensuring the final aesthetic appeal and lifespan. Hisea Marine provides detailed technical guidance.

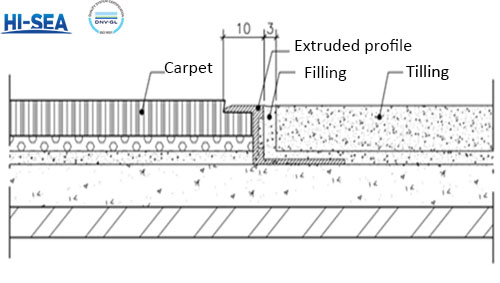

Picture