Introduction to the Structure and Principle of Marine Separators

In the field of shipping, marine separators play a crucial role in the effective operation and maintenance of ship power and lubrication systems. Firstly, it can be used for oil-water separation, effectively separating water from fuel oil or lubricating oil to ensure the purity of the oil. Secondly, it can remove solid impurities in fuel oil, such as various oxides and other contaminants, improving the quality of the oil and increasing the combustion efficiency. It also helps to maintain the proper performance and service life of marine engines and other equipment by ensuring the cleanliness and quality of the lubricating oil used.

Overview

The main structure of marine separator

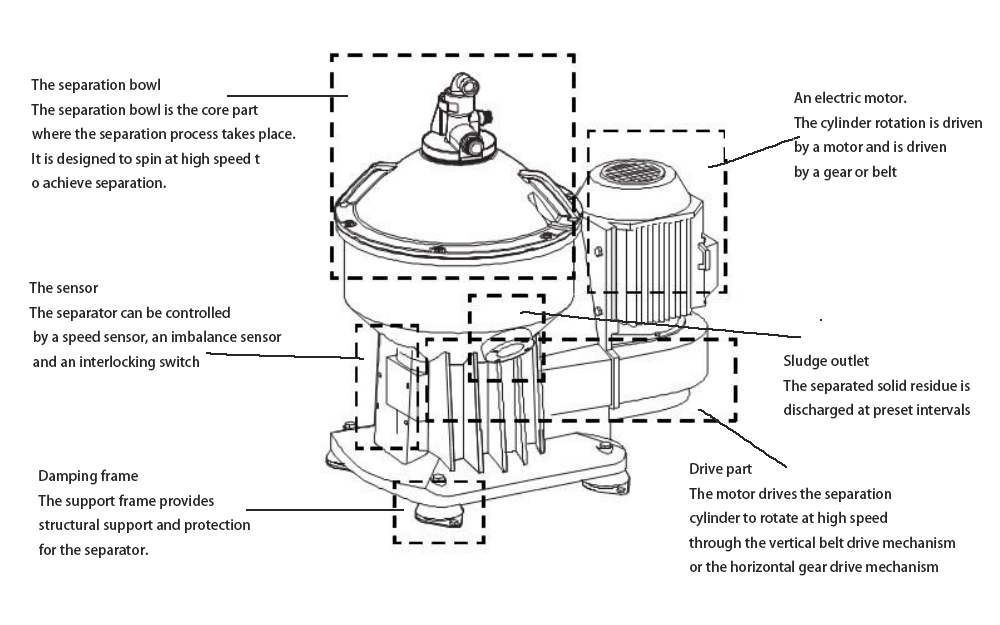

A marine separator typically consists of the following main components:

The separation bowl is the core part where the separation process takes place. It is designed to spin at high speed to achieve separation.

The drive unit is responsible for powering the rotation of the separation bowl, usually including a motor or other driving mechanism.

The inlet and outlet pipes are used for the inflow of the mixture to be separated and the outflow of the separated substances.

There are also various control valves and sensors to regulate the operation parameters such as flow rate, pressure, and temperature.

The supporting frame and housing provide structural support and protection for the separator.

Some advanced marine separators may also have additional components such as cleaning devices to maintain the cleanliness of the separation bowl and improve separation efficiency. Additionally, there may be systems for monitoring and adjusting the separation process in real-time to ensure optimal performance.

The basic principles of marine separator

The basic principle of separation The purpose of separation:

to remove solid particles from the liquid.

By different densities, two insoluble liquids are separated and solid particles in both liquids are removed.

To separate and concentrate solid particles from a liquid.

Separation by gravity

In a stationary separator, the liquid mixture will slowly become clear as the heavier particles in the liquid mixture settle to the bottom due to the influence of gravity. As heavier liquids and solids sink, lighter liquids rise. Continuous separation and settlement can be carried out in the settling cabinet. The settling tank is provided with various outlets according to the different density of the liquid. Only the heavier particles of the liquid mixture may settle at the bottom of the tank tank to form a precipitating layer.

Centrifugal separation

In a rapidly rotating separation cylinder, centrifugal force is many times greater than gravity, thus replacing gravity separation and precipitation are continuous and occur rapidly. The centrifugal force of the separation cylinder may be generated in a few seconds, while under the same gravity, it takes several hours. The separation efficiency is affected by changes in oil viscosity, separation temperature and yield.

Temperature

Because there are many different types of process liquids (e.g., mineral oils), higher separation temperatures generally improve separation performance.Temperature affects oil viscosity and density, so constant temperature should be maintained during the entire separation process.

Viscosity

Viscosity is the resistance within a liquid to flow. Low viscosity facilitates separation, and heating reduces accuracy.

Density difference

The difference in density per unit volume is very important. The greater the density difference between the two liquids, the easier it is to separate, and heating will increase the density difference.

Conclusion:

The above is the entire content of this article. In the article, we have detailedly introduced to you the structure and principles of marine separator. We hope that through this article, it can help you choose the marine separator.

Finally, if you have the need for procurement, you are welcome to visit our marine separator homepage or contact us at any time! Thank you again for your browsing!