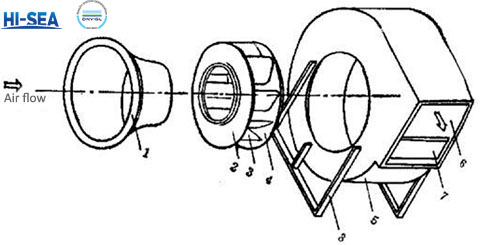

Installation of Marine Centrifugal Fan

The casing and air inlet of marine centrifugal fan are welded by ordinary steel materials and made into airtight structure.

Overview

Steps:

Before installation, check in detail whether the exhaust fan is damaged or deformed due to packaging and transportation. Only after it is properly repaired can the installation be carried out. During installation, pay attention to whether there is any looseness in each connection, and the gap between the blade and the blower barrel should be symmetrical and not collide.

The net weight of the pipeline connecting the vent shall not be borne by the centrifugal fan, and more support points shall be added during installation.

At the inlet end of the axial fan, the safety protection net can be modified according to the customer's needs.

The centrifugal fan base must be integrated with the subgrade, and it is not allowed to strike the anchor bolt for compulsory connection to prevent the deformation of the base.

If the centrifugal fan is used again after being idle for a long time, be sure to check whether a part of each connection is reliable and firm, and after the trial operation, the application can be announced.

After the centrifugal fan is declared to be running, check once a year whether the anchor bolts are loose, whether the blades are damaged too much, and whether the cable sheath is damaged. Repair or replace parts according to the actual situation.

Always pay attention to whether there is abnormal sound in the operation of centrifugal fan, and check and repair it immediately.

In addition to replacing the lubricating oil after each disassembly, it is also necessary to regularly check and replace the lubricating grease.

Drwaing: