Installation of Magnesium Ribbon Anode

Magnesium ribbon anode has flat shape, adjustable length, easy bending, good anti-corrosion performance and does not need external DC power supply. It operates automatically after installation, does not need maintenance, occupies less floor space, has low engineering cost and does not have any interference with the external environment. It is mainly used in high-resistance environment, protection of pipelines in casing, temporary cathodic protection of pipelines, protection of storage tanks and pipeline networks, and grounding grid against strong electric interference. Magnesium tape is mainly applied to the coiled body being protected, the surface with narrow construction space and high resistivity soil, fresh water and other media.

Overview

Selection and Calculation of Local Cathodic Protection Design

In the case of steel pipelines, local cathodic protection is widely used to protect pipelines against corrosion. The specific practice in the design process is to wrap a magnesium or zinc anode tape or install a bracelet anode on the main track in the casing. Local cathodic protection with a magnesium anode tape is usually recommended.

The amount of sacrifice anode for local cathodic protection in the casing can be calculated according to the protection area and the quality of the required anode can be obtained.

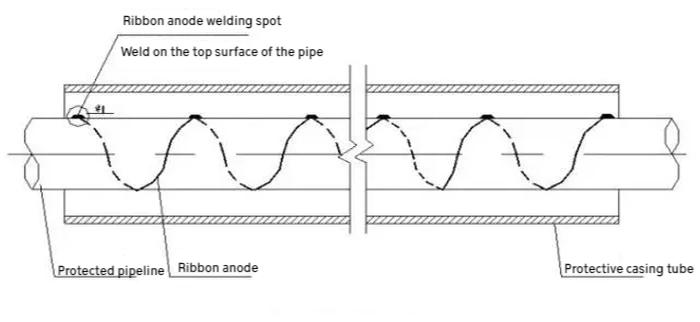

Schematic Installation of Magnesium Ribbon Anode

Method for Cathodic Protection of Wrapped Magnesium Ribbon Anode

When installing the magnesium anode belt, the method of mechanical polishing can be used to expose the inside of the steel pipe 3cm ~ 5cm, and the appropriate solder joint is dug on the main pipe. The magnesium anode belt is welded to the main pipe by electric welding, alumino-thermal welding and other welding methods. According to the different pipe diameters, the outer wall of the pipe is tightly wound, and the two solder joints should be insulated and anti-corrosion. After the winding construction of magnesium anode belt, both ends of the casing should be sealed with flexible anti-corrosion and waterproof materials, and ensure good sealing to prevent water or other sundry objects from entering.

Picture of Magnesium Ribbon Anode