Inline Blower

Inline blower is a kind of equipment mainly used for conveying gas, which is mainly composed of two parts: motor and impeller. When the motor is activated, air flow is generated by the rotation of the impeller, which is then sent into the duct for transportation. Inline blower do not have electric wires because it is based on the principle of generating air flow through the rotation of the impeller, which does not require electric wires as a conduction medium. Inline blowers are made by changing the shape of the blades so that the airflow, after entering the fan, is both partially axial and partially centrifugal, so their performance is between axial flow fans and centrifugal fans.

Overview

Application:

One of the most important functions of inline blowers is ventilation and air exchange. In enclosed environments, such as basements, kitchens, and bathrooms, inline blowers can help exhaust dirty air and bring in fresh air, making the air in these spaces fresher. In the hot summer months, indoor temperatures are often higher than outdoor temperatures.

At this time, inline blower can help lower indoor temperatures by expelling hot air from the room while bringing in cooler air from outside.

In humid environments, such as basements or during the rainy season, inline blowers can help remove moisture and reduce humidity for a more comfortable environment.

Inline blowers are usually installed in hard-to-reach places, such as under ceilings or floors. To ensure their proper functioning, low-noise models are usually used.

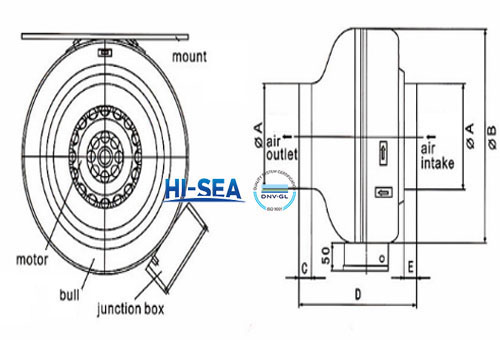

Drawing:

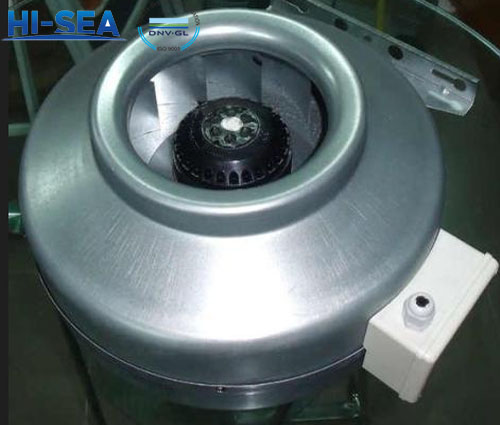

Picture: