IMPA 872339 Air Vent Head

Overview

Material selection

Many relatively inexpensive Air Vent Heads are designed using a welded plate to keep the cost down. In some cases, the material thickness is below 6 mm and the material are normal steel plates. These Air Vent Heads have a tendency not to last the required 5 years and the corrosion rate is high.

It is recommended that due to the applications areas of the Air Vent Head, that the valve body should be a casted metallic design, made in corrosion resistant material or be applied a coating that prevents corrosion. This could be cast ductile iron, or seawater resistant aluminum even though some authorities do not accept sea resistant aluminum. Stainless steel has also been abandoned as body material due to high corrosion rates.

A design in seawater resistant aluminum is lighter than that cast iron or stainless steel, but a steel body has high resisters towards mechanical impact. Aluminum Nickle bronze alloy is better than both cast iron and aluminum when looking at both corrosion and durability, but it is also expensive.

It is suggested that a coating should be according to corrosion category 4/5, marine standard (offshore application) to protect both exterior and interior parts against corrosion.

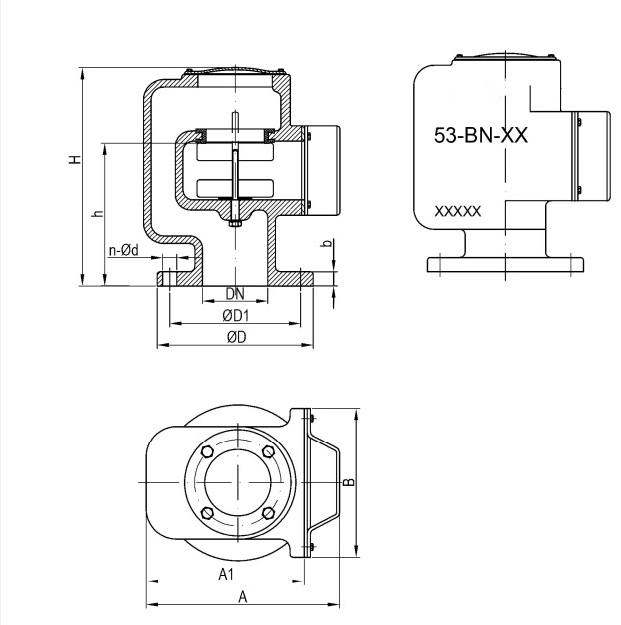

Drawing

Images of IMPA 872339 Air Vent Head

DN | A | A1 | B | D | D1 | n-0d | D2 | m | h | H |

50 | 180 | 140 | 135 | 130 | 105 | 4-15 | 60 | 17 | 125 | 185 |

65 | 205 | 167 | 145 | 155 | 130 | 4-15 | 75 | 22 | 160 | 215 |

80 | 235 | 195 | 160 | 180 | 145 | 4-19 | 90 | 27 | 195 | 260 |