Hydraulic Anchor Windlass

A hydraulic anchor windlass is a piece of machinery commonly used on ships to raise and lower anchors. It's a vital component for maritime vessels, as it helps in anchoring operations. It is driven by a hydraulic motor. The hydraulic system powered by the electro-hydraulic power unit(HPU), diesel engine hydraulic power pack or PTO . The hydraulic system provides the power necessary to operate the windlass efficiently, allowing it to handle heavy anchor chains and anchors with ease. It plays an important role of the hydraulic anchoring system. It is widely installed on a variety of ships. When a vessel is about to sail or berth, the anchor windlass will raise or lower anchors through anchor chain.

1. Driven by hydraulic motor

2. Hand proportional valve, step-less speed

3. Clutch & brake: manual or hydraulic operated

4. Local control or remoto control unit

5. Overload protection, emergency stop functions

Overview

The hydraulic anchor windlass is driven by an electric motor to operate a hydraulic pump, converting the mechanical energy of the electric motor into hydraulic energy and generating high-pressure oil. High pressure oil drives the oil motor, which then converts hydraulic energy into mechanical energy to drive the output shaft of the oil motor to rotate. After passing through the reducer, it drives the sprocket or drum of the anchor machine to rotate, achieving operations such as anchoring, anchoring, and chain cable winding.

There is a clutch between the sprocket and the transmission main shaft. When the clutch is engaged, the sprocket and main shaft are interlocked and can rotate together with the main shaft, thereby twisting in or out the anchor chain; When the clutch is disengaged, the sprocket does not rotate with the main shaft and can be used for anchoring or cable twisting operations. The braking device is used to brake the anchor chain or control the speed of loosening the chain. When the brake is tightened, the sprocket is firmly attached to the anchor machine body and cannot rotate.

The basic components of a hydraulic anchor windlass include a hydraulic motor, a gearbox, the gypsy wheel around which the anchor chain is wound, brake, clutch, control system, hydraulic pump station, etc.

Features

Advantage:

Compact structure, small volume of power and transmission parts, and less occupation of deck space;

Easy installation, smooth operation,

Good transmission performance, able to achieve stepless speed regulation, and can accurately control the anchoring and anchoring speed according to actual needs;

The hydraulic system has overload protection function. When the load exceeds a certain value, the hydraulic pump will automatically unload to protect the safety of the equipment;

High work efficiency, able to quickly anchor and drop anchor, improving the operational efficiency of ships.

Disadvantages:

High requirements for manufacturing technology and maintenance

Professional technicians are required for installation, debugging, and maintenance;

The oil in the hydraulic system is easily contaminated and needs to be replaced and filtered regularly to ensure the normal operation of the system;

The price of hydraulic components is relatively high, and once a malfunction occurs, the maintenance cost is also relatively high.

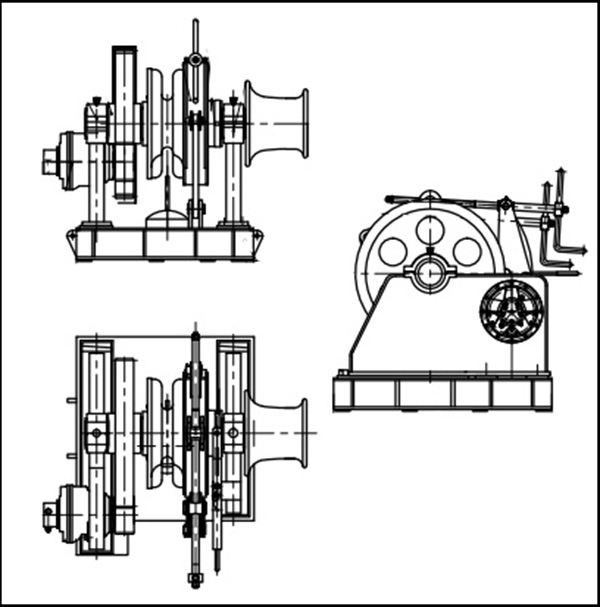

Drawing of Hydraulic Anchor Windlass

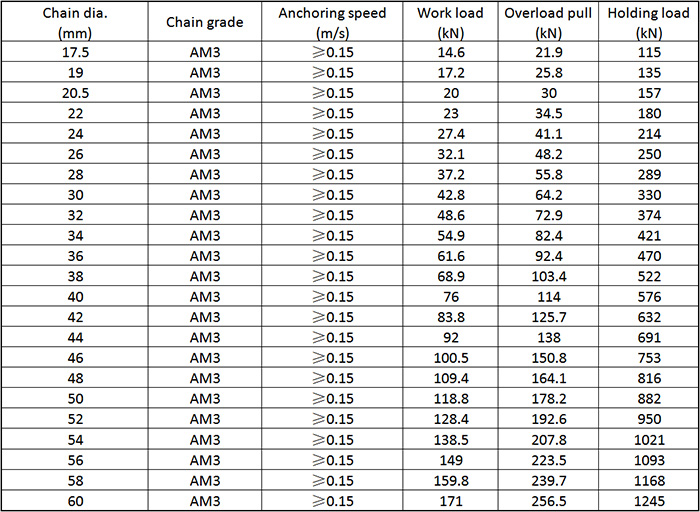

Main Technical Parameter (only for reference)