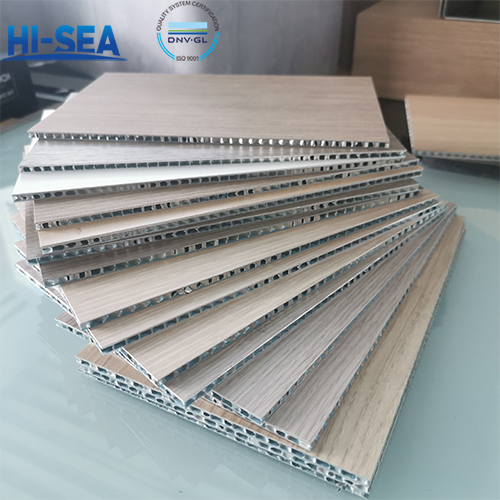

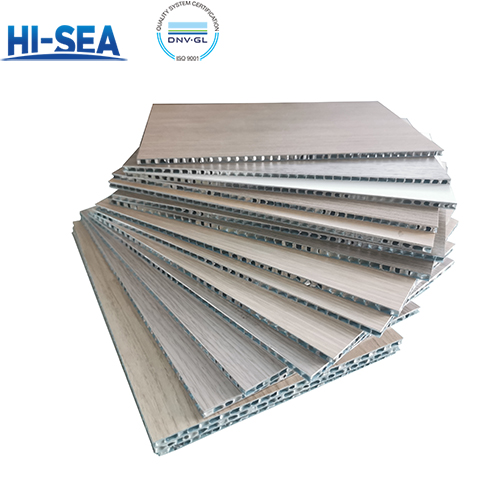

HPL Laminate Honeycomb Panels

HPL (High-Pressure Laminate) Honeycomb Panels are composite materials used extensively in various industries due to their lightweight yet strong and durable nature. HPL honeycomb panels represent a versatile and high-performance solution for a variety of applications where lightweight, strength, and durability are required.

Overview

Composition and Structure

Core: The core of HPL honeycomb panels is typically made from a lightweight honeycomb structure, often composed of materials like aluminum or aramid (Nomex®). This honeycomb structure gives the panel high strength-to-weight ratios, making it both lightweight and structurally robust.

Facings: The surfaces or facings of these panels are made from high-pressure laminate (HPL). HPL is created by pressing and heating multiple layers of kraft paper impregnated with phenolic resin and a surface layer of decorative paper impregnated with melamine resin. This results in a hard, durable surface that is resistant to impact, moisture, chemicals, and wear.

Features

Durability: HPL surfaces are highly resistant to scratching, impact, moisture, and chemicals, ensuring a long service life even in demanding environments.

Thermal and Acoustic Insulation: The air-filled honeycomb core offers good thermal and acoustic insulation properties.

Aesthetic Versatility: HPL comes in a wide range of colors, patterns, and textures, allowing for versatile design options.

Picture of HPL Laminate Honeycomb Panels