How to Choose Marine Angle Valve

Options for marine angle valves made from corrosion-resistant materials such as bronze, brass, cast steel, cast iron, stainless steel or stainless steel. These materials can withstand the harsh marine environment and prevent corrosion.

Overview

Application Specifics:

Consider any specific requirements or conditions of your marine application, such as temperature extremes, exposure to seawater, or vibration. Choose a valve that is designed to withstand these conditions and perform reliably in the marine environment.

Size:

Select the size of the valve based on the diameter of the pipes it will be connected to. Ensure that the valve's size matches the size of the pipes to ensure proper flow and functionality.

Pressure Rating:

Consider the pressure rating of the valve to ensure it can withstand the operating pressure of your marine system. The pressure rating should be suitable for the maximum pressure expected in your application.

End Connections:

Determine the type of end connections required for your marine application, whether threaded, flanged, or welded. Ensure that the valve's end connections are compatible with the piping system it will be installed in.

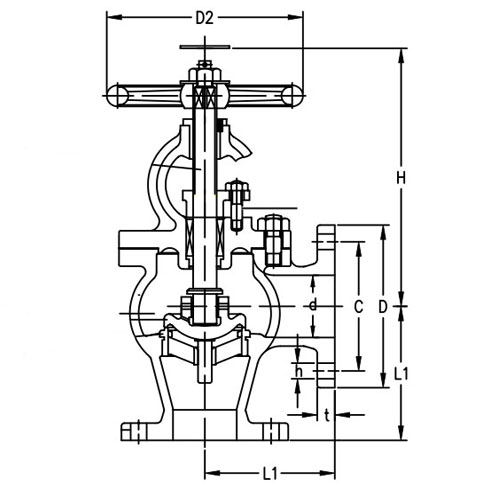

Drawing:

Image of product:

MAIN DIMENSIONS | |||||||||

Size | L | D | C | No. | h | t | H | D2 | Kg |

50 | 210 | 130 | 105 | 4 | 15 | 16 | 270 | 160 | 14.7 |

65 | 250 | 155 | 130 | 4 | 15 | 18 | 300 | 180 | 21.3 |

80 | 280 | 180 | 145 | 4 | 19 | 18 | 310 | 180 | 27.7 |

100 | 340 | 200 | 165 | 8 | 19 | 20 | 360 | 224 | 40.8 |

125 | 410 | 235 | 200 | 8 | 19 | 20 | 390 | 250 | 57.6 |

150 | 480 | 265 | 230 | 8 | 19 | 22 | 445 | 280 | 80.3 |

200 | 570 | 320 | 280 | 8 | 23 | 24 | 530 | 315 | 139 |

250 | 740 | 385 | 345 | 12 | 23 | 26 | 650 | 355 | 216 |

300 | 840 | 430 | 390 | 12 | 23 | 28 | 740 | 400 | 346 |

350 | 940 | 480 | 435 | 12 | 25 | 30 | 840 | 500 | 418 |

400 | 1050 | 540 | 495 | 16 | 25 | 30 | 940 | 630 | 600 |