How many kinds of container securing fittings

Overview

Fixed fittings are welded on the ship's hold or deck, hatch cover, and pillars, serving as lashing points and support structures. Common types include foundations, guide fittings, lashing eyes, weldable cones, and D-rings.

Foundations are typically welded on the deck or hold and used to position and secure containers using twist locks or stacking cones. Types include raised foundations, twistlock pocket, dovetail foundations, and base foundations.

Guide fittings support and secure cargo to prevent movement during sea transport, ensuring stability and ship safety.

Lashing eyes act as lashing points and are used with lashing bars and turnbuckles to secure containers. They come in single, double, and triple eye plate types.

Weldable cones are welded to the corners of the ship's hold and used to secure the bottom layer of containers by inserting them into container corner fittings.

D-rings are mainly used on hatch covers, decks, container pillars, and lashing bridges as lashing points, used with lashing bars and turnbuckles.

Loose fittings are tools for securing containers on the deck. Types include twistlocks, stacking cones, lashing bars, turnbuckles, extension rods, and bridge fittings.

Twistlocks secure containers vertically or horizontally between layers or between containers and the ship's hull. They come in various types, including bottom twistlocks, midlocks, semi-automatic twistlocks, and fully automatic twistlocks.

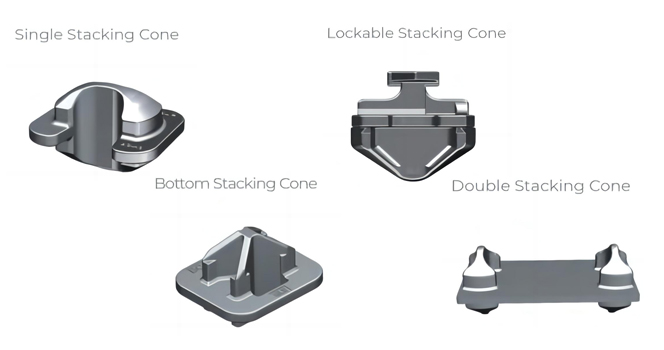

Stacking cones prevent horizontal movement between stacked containers. They are commonly used to secure 20-foot containers on the deck when loading 20-foot containers on 40-foot container slots.

Lashing systems consist of lashing bar, turnbuckles, extension rods, and lashing eyes. These tools stabilize and secure containers on the deck during stacking operations. When stacking containers on the deck, lashing bars are crisscrossed and tightened with turnbuckles to prevent swaying or sliding. Extension rods are used when lashing bars are not long enough.

Bridge fittings horizontally connect adjacent containers on the top layer at the same height. They are inserted into the corner fittings of adjacent containers and tightened by rotating adjustment nuts.