High Temperature Resistant Fire Damper

High temperature resistant fire dampers are mainly used on the air ducts of ventilation systems with fire prevention requirements. When a fire occurs, once the temperature inside the air duct rises above 70 ℃, the fire damper will quickly and automatically close to achieve regional isolation and prevent the spread and expansion of fire along the air duct. The control form adopts a rotary cylinder.

The fire damper is designed and manufactured using specialized fixtures, with small deformation, low air leakage, and good reliability; Equipped with relevant signal feedback, it can achieve automated control.

Overview

Performance advantages

1.Good fire prevention effect: High temperature resistant fire dampers can effectively control the spread of fire, limit the scope of fire, and protect people's lives and property safety. This is because the fire damper is made of high-quality materials, which have good fire resistance and service life, and are not prone to failure.

2.Safe and reliable: The structure of the fire damper is simple, easy to maintain, and can be used for a long time after installation. The design and material selection of this valve ensure its stability and reliability in various environments.

3.Low cost: The price of fire dampers is relatively low and generally acceptable, and the investment cost of buildings will not increase too much as a result. This provides an economically efficient solution for construction projects.

4.Good air tightness performance: High temperature resistant fire dampers have the characteristic of low air leakage, ensuring their good air tightness performance, which is crucial for improving the energy efficiency and comfort of buildings.

5.Strong anti-corrosion performance: These valves are usually made of materials such as stainless steel, which have good anti-corrosion performance and thus extend their service life.

6.Flexible actuator drive: The actuator design of the fire damper is flexible, providing accurate feedback and interlocking signals, and supporting manual, electric, and automatic adjustment devices.

7.Temperature control: Some fire dampers are equipped with temperature fuses, such as a device that melts at 70 ℃, to ensure automatic closure at specific high temperatures, further enhancing their fire safety.

Installation points

1.If the installation position of the fire damper (ship fire damper) on the air duct is higher than 2 meters, it should be led down with ropes, and the operating position is generally 1.5 meters above the ground.

2.When the ship's fire damper (ship's fire control damper) needs to be operated on both sides, if steel wire ropes are used, the total length of the steel wire ropes shall not exceed 6m, the number of bends shall not exceed 3, and the bending radius shall not be less than 300mm. DN20 steel pipes shall be used as sheaths for the ropes.

3.Fire dampers and remote control solenoid valves installed in hazardous areas should be placed together with the control box in a safe area.

4.The remote control device (box) is installed at a height of 1.5m above the ground.

5.The control of the fire damper (marine fire damper) on the kitchen exhaust duct should consider interlocking with the release of carbon dioxide, and the control box should be placed near the kitchen door.

6.The air vent fire damper in the emergency generator room should be interlocked with the starting of the diesel generator. According to ISO requirements, the fire damper in the emergency generator room usually adopts a non fault closing form.

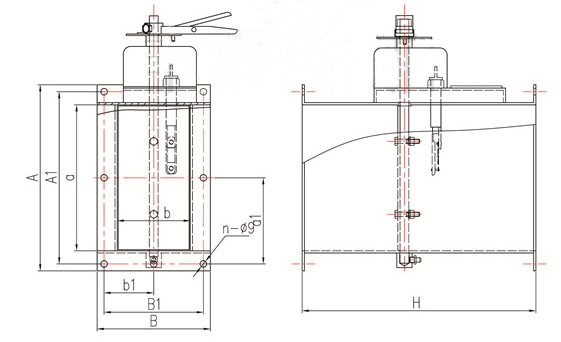

Drawing: