Galvanized Wire Ropes

Galvanization involves coating the steel wire with a protective zinc layer. Zinc coating provides superior protection against rust and harsh weather. Thick galvanized wire ropes are an ideal solution for the needs of heavy lifting equipment. HI-SEA MARINE offers a comprehensive selection of galvanized wire ropes, available in various constructions and diameters to meet specific needs.

Overview

Galvanized-to-Finish Wire:

Galvanization is a steel post-treatment where carbon steel is coated with zinc. The common methods include hot-dip galvanizing, where steel is dipped in molten zinc, and electro-galvanizing, which uses an electric current to apply the coating. In galvanized wire production, the wire is made slightly smaller than its final diameter and then coated with a thick zinc layer to reach its intended size.

Benefits of galvanized wire rope:

Long lifespan.

Affordability.

Strong and durable.

Low maintenance costs.

Resistance to rust & corrosion.

Withstand extreme temperature.

Galvanized steel wire rope offers greater durability than bright steel wire rope in wet and corrosive environments, significantly extending its service life. Besides, its zinc coating provides a level of corrosion resistance nearly equivalent to that of uncoated stainless steel. While stainless steel works well for many applications, high carbon steel is essential for handling heavier loads.

Applications of Galvanized Wire Rope:

Securing Heavy Loads on a dockyard or ship.

Support large structures, such as bridges.

Mooring and anchoring, stabilizing a heavy load or structure.

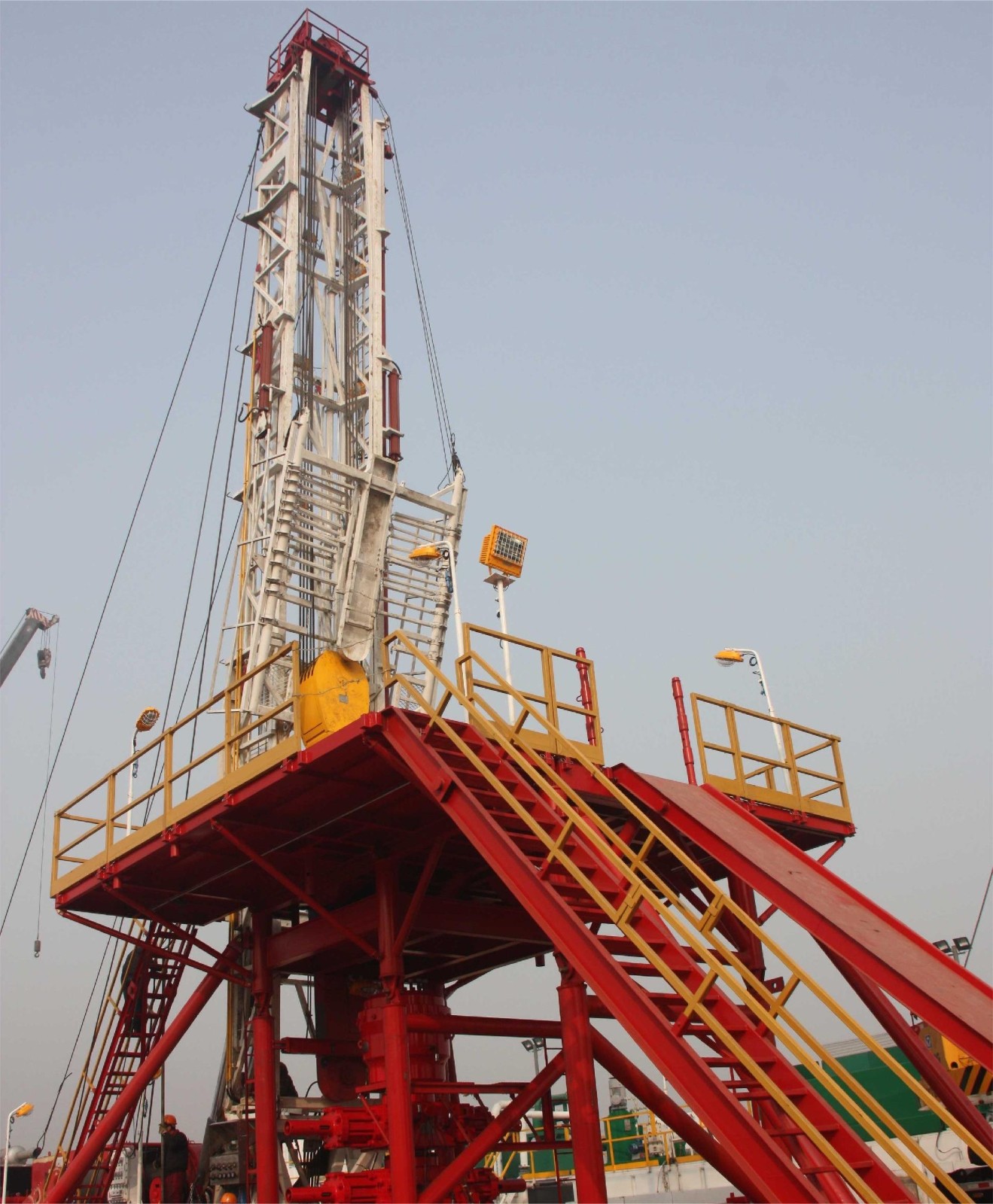

For factory hoists, construction cranes, dockyard gantry cranes, mine loaders, and many other heavy lifting equipment.