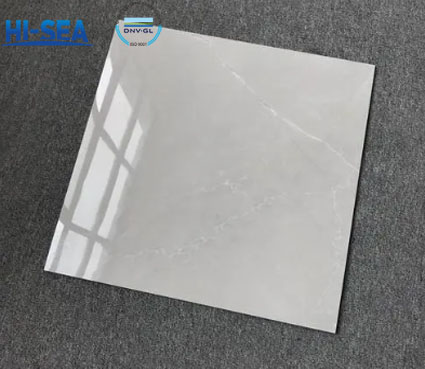

Full Polished Porcelain Tile

Full Polished Porcelain Tile is a glazed surface can be polished process of a special formula glaze, its body process is similar to the general glazed floor tiles, the main difference is that it is after the bottom glaze on the printing, and then apply a layer of transparent surface glaze, firing the entire surface glaze thrown off a part of the glaze to retain a portion of the surface glaze layer, the printing layer, the bottom glaze, the main objective of full polished tiles is to Instead of polished tiles.

Overview

Difference:

Fully glazed ceramic tile blanks do not use high-quality raw materials, the surface layer as long as there is about 0.5-1mm glaze layer can be.

And polished tiles also need 2-3mm of fine material; glazed tile pattern simulation is easy to do well, the cost is also low. Fully glazed ceramic tile production is more environmentally friendly, due to the glaze layer firing faster, lower energy consumption, glazed than polished energy consumption is low and production is also higher.

Picture:

Size | ||

300*300mm | 300*600mm | 400*400mm |

400*800mm | 600*600mm | 800*800mm |

600*1200mm | 750*1500mm | 900*1800mm |