FUB Rubber Air Duct compensator

FUB Rubber Air Duct compensator is a kind of duct connection equipment used to connect various fans and ducts flexibly, with good vibration and noise damping, heat and dust insulation ability, applicable to a variety of industrial fields in the duct system.

Overview

Function

Vibration damping: Effectively absorbing the vibration generated by the pipeline due to thermal expansion and contraction or fluid impact, reducing the vibration during operation.

Noise reduction: by absorbing the noise of pipeline operation.

Sealing: It has good sealing performance to prevent medium leakage.

Resistant to medium: able to adapt to various medium environments.

Installation: simple structure, easy to install.

Application Fields

Ventilation system: Used to connect fans and ducts to absorb vibration and displacement.

Air conditioning system: Used to connect hot and cold air ducts, to compensate for the expansion and contraction of the ducts caused by temperature changes, and to reduce vibration and noise.

Heating system: used to connect hot water or steam pipes.

Dust extraction and smoke exhaust system: used to connect dust collector and smoke exhaust piping, absorbing vibration and displacement generated by the operation of the equipment.

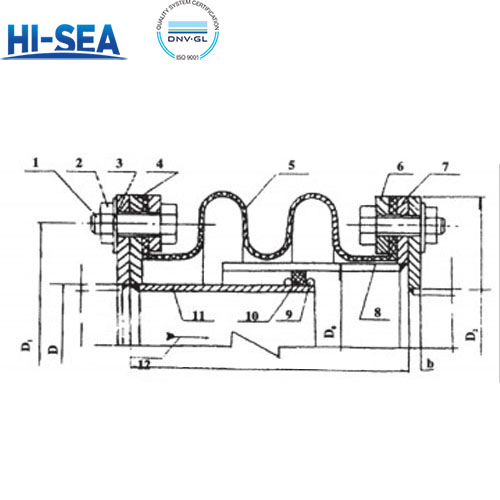

Materials Table | |||

No | Name | Material | Quantity |

1 | Flange | Q235flat steel, angle steel | 2 |

2 | Inner and outer layer | Natural rubber, synthetic rubber | 1 |

3 | Enhancement layer | Hanging plastic labric | 2-4layers |

4 | The inner sleeve | Q235 A3 | 1 set |

5 | Outer sleeve | Q235 A3 | 1 set |

6 | Seals | Natural rubber, synthetic rubber | 1 |

Product technical performance indicators | ||

Technical performance | Product Model | FUB |

Compensation length | ±90mm | |

Working pressure | ≤50KPa | |

Humidity range | -40℃-150℃ | |

Installation length | 300-450mm | |

Stretching the length of the rate of change | ≤15% | |

Sum of sliding bracket distances at both ends | ≤50m | |

Rubber properties | Spacing between sliding brackets at both ends | 2-4m |

Tensiie strength | ≥12mpa | |

Elongation at break | ≥300% | |

Ultimate permanent deformation | ≤25% | |

Hardness | 58± 3° | |

Coefficient of hot air aging (70 C x72h) | 0.85 | |

Elongation at break of the rate of change | ≤20% | |

Type mm | Tube diameter D | D1 | D2 | D3 | Flange thickness mm | The number of connecting bolts | Weight kg |

FUBB00 | 812 | 950 | 1000 | 850 | 8 | 24xM22 | 184.6 |

FUB900 | 912 | 1050 | 1100 | 950 | 203.6 | ||

FUB1000 | 1012 | 1150 | 1200 | 1052 | 10 | 30xM22 | 221.9 |

FUB1100 | 1112 | 1250 | 1300 | 1152 | 240.7 | ||

FUB1200 | 1212 | 1350 | 1400 | 1252 | 259.5 | ||

FUB1300 | 1312 | 1450 | 1500 | 1352 | 278.3 | ||

FUB1400 | 1412 | 1550 | 1600 | 1452 | 30xM22 | 357.3 | |

FUB1500 | 1512 | 1650 | 1700 | 1552 | 36xM22 | 291.2 | |

FUB1600 | 1614 | 1750 | 1800 | 1654 | 10 | 426.3 | |

FUB1700 | 1714 | 1850 | 1900 | 1754 | 449.7 | ||

FUB1800 | 1814 | 1950 | 2000 | 1854 | 44xM22 | 481 | |

FUB1900 | 1914 | 2020 | 2120 | 1954 | 533.4 | ||

FUB2000 | 2016 | 2170 | 2240 | 2056 | 619.9 | ||

FUB2100 | 2116 | 2270 | 2340 | 2156 | 12 | 54xM30 | 753.3 |

FUB2200 | 2216 | 2370 | 2440 | 2256 | 785.3 | ||

FUB2300 | 2316 | 2470 | 2540 | 2356 | 817.2 | ||

FU82400 | 2416 | 2570 | 2640 | 2456 | 849.2 | ||

FUB2500 | 2516 | 2670 | 2740 | 2556 | 881.2 | ||

FUB2600 | 2616 | 2770 | 2840 | 2656 | 14 | 64xM30 | 913.2 |

FUB2800 | 2816 | 2970 | 3040 | 2856 | 986.5 | ||

FUB3000 | 3016 | 3170 | 3240 | 3056 | 1050.5 | ||

FU83200 | 3216 | 3370 | 3440 | 3256 | 1114.6 | ||

FUB3400 | 3420 | 3580 | 3660 | 3480 | 16 | 72xM30 | 1443.9 |

FU83500 | 3520 | 3680 | 3760 | 3580 | 1484.7 | ||

FUB3600 | 3620 | 3780 | 3860 | 3680 | 1525.4 | ||

FUB3800 | 3820 | 3980 | 4060 | 3880 | 80xM30 | 1606.9 | |

FUB4000 | 4020 | 4180 | 4260 | 4080 | 1688.3 | ||

FUB4200 | 4220 | 4380 | 4460 | 4280 | 1769.8 |