Foam Filled Fender

Foam filled fender, also known as solid polyurethane fender, is a rubber fender filled with foam materials. The following is the analysis of foam filled fenders:

Cushioning performance: The foam materials (such as foamed EVA, foamed polyurethane or foamed rubber) inside the fender provide good cushioning performance, which can effectively absorb and disperse the impact force generated when the ship docks or moors.

Structural stability: foam material increases the overall stability and structural strength of the foam filled fender, making it not easy to deform or damage under impact.

Durability: Due to the addition of foam materials, foam filled fenders usually have a long service life and low maintenance costs.

Maintenance: foam filled fenders do not need regular inflation or filling, which reduces maintenance work and is suitable for use in harsh environments.

Self floating characteristics: foam filled fenders are designed as floating type, which can float freely on the water surface, and are suitable for wharfs with large tide level changes.

Simple installation: the installation of foam filled fenders is usually relatively simple, which can be quickly installed and adjusted as required.

Overview

Description:

Foam filled fender, also known as solid polyurethane fender, is a rubber fender filled with foam materials. The following is the analysis of foam filled fenders:

1. Cushioning performance: The foam materials (such as foamed EVA, foamed polyurethane or foamed rubber) inside the fender provide good cushioning performance, which can effectively absorb and disperse the impact force generated when the ship docks or moors.

2. Structural stability: foam material increases the overall stability and structural strength of the foam filled fender, making it not easy to deform or damage under impact.

3. Durability: Due to the addition of foam materials, foam filled fenders usually have a long service life and low maintenance costs.

4. Maintenance: foam filled fenders do not need regular inflation or filling, which reduces maintenance work and is suitable for use in harsh environments.

5. Self floating characteristics: foam filled fenders are designed as floating type, which can float freely on the water surface, and are suitable for wharfs with large tide level changes.

6. Environmental protection characteristics: foam filling materials are usually environmental protection materials, which have little impact on the environment.

7. Simple installation: the installation of foam filled fenders is usually relatively simple, which can be quickly installed and adjusted as required.

8. Applicability: foam filled fenders are suitable for various ship and wharf environments, especially under severe conditions such as offshore drilling platforms requiring additional protection.

Foam filled fenders have been widely used in modern ports and ship protection facilities because of their excellent protective performance and durability.

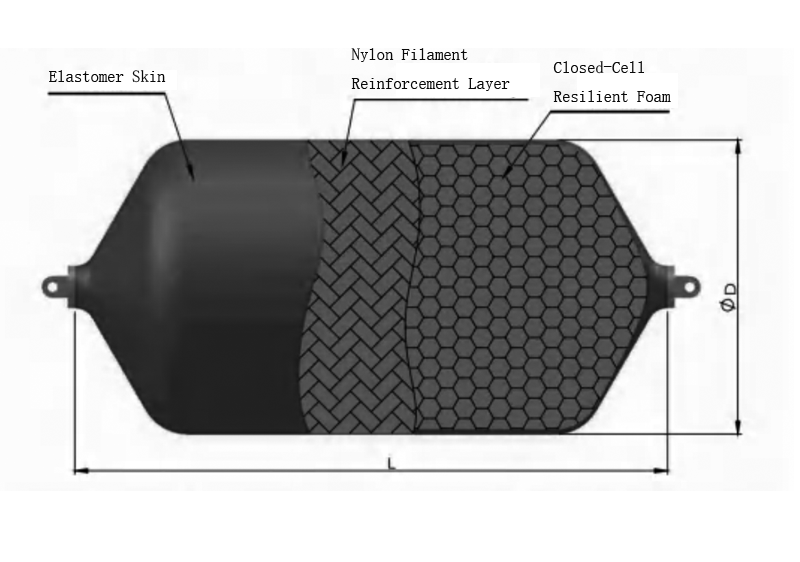

Drawing of Foam Filled Fender:

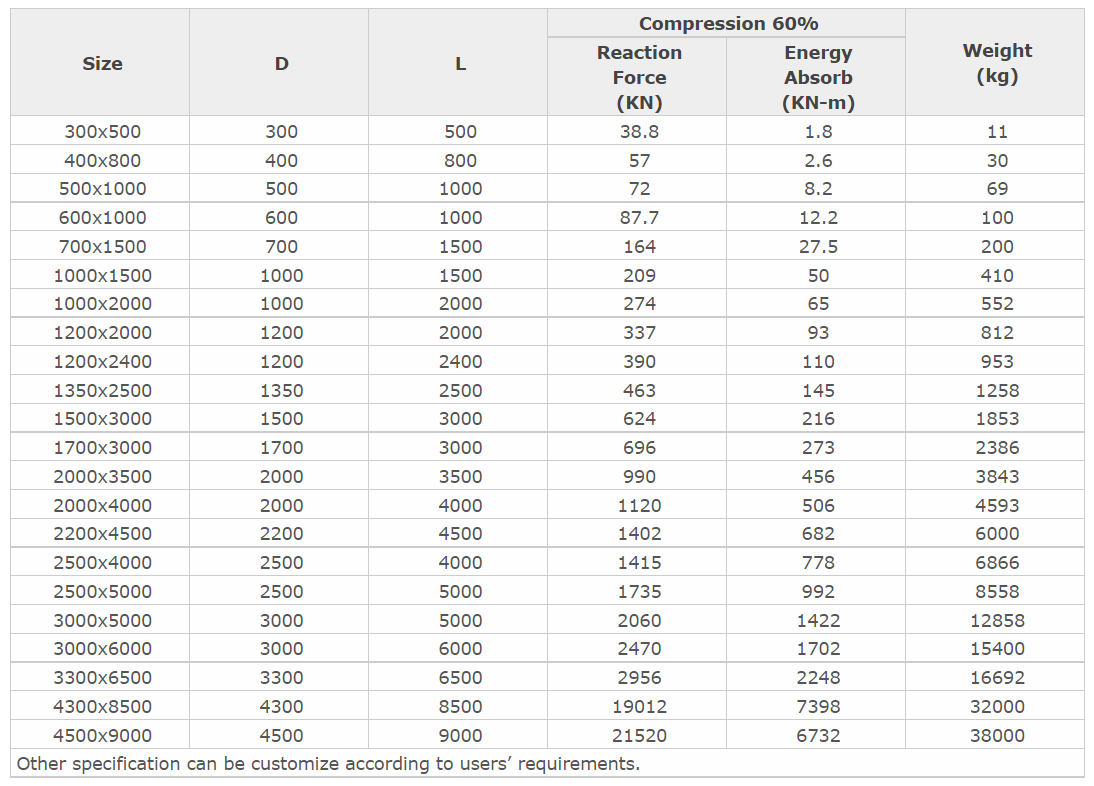

Specification of Foam Filled Fender:

Different Color Foam Filled Fender:

The color of Foam Filled Fender can be customized according to your needs.

Foam Filled Fender with Chain Net:

Chain net with tyre can protect the Foam Filled Fenders from damage, effectively extending the service life of the Foam Filled Fenders.