Floating Floor

Hisea Marine's floating floor systems are engineered to effectively isolate structure-borne noise and vibration from the ship's hull, creating quieter and more comfortable living and working spaces in cabins, mess rooms, and wheelhouses. Our solutions help meet stringent acoustic comfort standards and regulatory requirements.

Overview

The following illustrates a standard installation process for our composite floating floor system. Hisea Marine provides detailed technical supervision and support to ensure optimal performance.

Process Requirements:

1. To prevent bending of the rock wool, remove all debris from the steel deck before laying rock wool directly on the steel deck.

2. Lay the rock wool (50 mm thick) close together without gaps between the rock wool. At the same time, lay the rock wool in staggered seams so that the seams do not run in a line (

3. Lay steel strips on top of the rock wool, with specifications of 140mm x 2000mm x 1.5mm.

4. lay steel plate (specification 1000mm×2000mm×2mm, electro-galvanized) on the steel strip, each corner of the steel plate at a distance of 5cm and the edge of the ring steel plate every 25cm are spot welded, and before laying the next layer of the spot welding position must be polished.

5. Pre-measure and pre-cut the 3mm steel sheets before applying the Sika Damping, and then remove the cut sheets.

6. Apply Sika Damping with a sawtooth trowel to a thickness of 1.5 mm, the area of Sika Damping to be applied being slightly larger than the area of the steel plate to be laid at any one time.

7. Press a 3mm steel plate (1000mm x 2000mm x 3mm, electro-galvanized) directly onto the wet Sika Damping layer.

8. Floating floors are to be laid at a distance of 10mm from bulkheads, hull structures, through-hull members, etc. and the edges sealed with Sika damping.

Our Floating Floor Systems

Complete Floating Floor Kit: Includes prefabricated rock wool panels, galvanized steel sheets, and all connectors.

Standard and Custom Designs: Offers standard sound insulation solutions for various ship areas (above-engine cabin, living quarters, public areas, etc.), and also supports customized engineering designs.

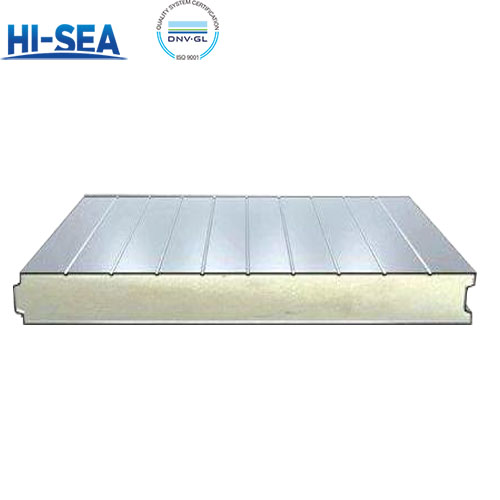

Picture

Fire Class | A-60 |

Dimension | 450mm Width(Max) 1230mm Length (Max) |

Weight | 125.6kg/m²(47.1Kg/m² Floating floor+78.5Kg/m² Deck |

Thermal transmittance | 0.49Kcal/m²h℃ |

Tolerances | Width°-1*Length±1*Thickness°-1 |

Combination sound reduction | 51~54dB |