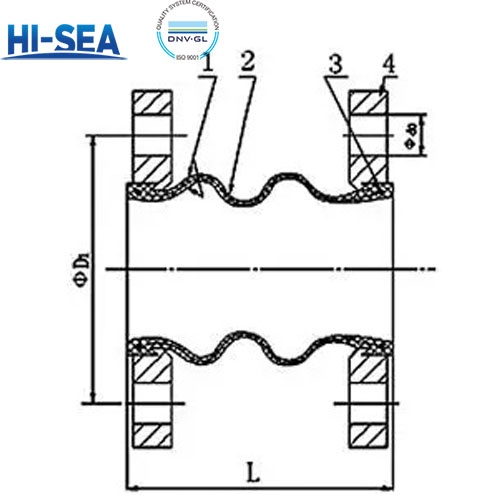

Flexible Double-ball Rubber Joint

Flexible double-ball rubber joint is a high-performance pipeline connector with high elasticity, media resistance and weather resistance, mainly used for pipeline vibration and noise reduction and compensation of displacement, absorption of stress generated by the pipeline, to ensure the safety and stability of the pipeline system.

Overview

Structure material

Inner rubber layer: high-quality rubber materials are used, such as natural rubber, nitrile rubber, EPDM rubber, fluorine rubber and so on.

Reinforcement layer: nylon cord fabric or steel wire rope is used for reinforcement to improve the pressure-bearing capacity and tensile strength of the joint.

Outer rubber layer: adopt wear-resistant and weather-resistant rubber materials, such as natural rubber, nitrile rubber, etc.

Flange: carbon steel flange is used, and the material and thickness of the flange can be customized according to the specific needs to ensure that the joint is firmly and stably connected.

Application fields

Water supply and drainage system: used for connecting and fixing pipes to ensure smooth water flow and reduce the impact of water flow on pipes.

Circulating water system: enough to absorb the thermal expansion and contraction of the pipeline, to maintain the stability of the system.

HVAC System: Enough to absorb vibration and noise and improve the comfort of the system.

Fire-fighting system: able to respond quickly and ensure the smooth transportation of fire-fighting water.

Paper, pharmaceutical, petrochemical: withstand the high temperature, high pressure and high corrosive environment, to ensure the safe and stable operation of the piping system.

Building water supply and drainage: the head can absorb displacement and vibration, to protect the stability and safety of the piping system.

Electric power: effectively alleviate the impact of temperature on the piping system, to ensure the stable operation of power equipment

Technical conditions | |||

Ltem Nominal Diameter DN | 200~300(8-12’’) | 50~100(2-6’’) | |

KXT(JGD)-A(I) | KXT(JGD)-A(II) | KXT(JGD)-A(III) | |

Working pressure Mpa (kgf/cm2) | 1.0(10) | 1.6(16) | 2.5(25) |

Burst pressure Mpa (kgf/cm2) | 2.0(20) | 3.0(30) | 4.5(45) |

Vacuum degree Kpa(mm/Hg) | 40(300) | 53.3(400) | 86.7(650) |

Suitable temperature℃ | -30 To +250 -15 to +115 special | ||

Suitable medium | Air、compressed air、water、sea water、hot water、oil、acid、alkali and other chemicals | ||

The main data | ||||||||||

Nominal Diameter DN | Length L mm | Flange thickness b mm | Number of bolts n | The diameter of the bolt hole mm | Bolt hole center Circle diameter mm | Axial displacement mm | Lateral displacement mm | Deflection angle(α1+α2) | ||

mm | inch | Elongation | Compression | |||||||

50 | 2 | 165 | 18 | 4 | 17.5 | 125 | 30 | 50 | 45 | 35° |

80 | 3 | 175 | 20 | 8 | 17.5 | 160 | 35 | 50 | 45 | 35° |

100 | 4 | 225 | 22 | 8 | 17.5 | 180 | 35 | 50 | 40 | 35° |

125 | 5 | 230 | 24 | 8 | 17.5 | 210 | 35 | 50 | 40 | 35° |

150 | 6 | 325 | 24 | 8 | 22 | 240 | 35 | 50 | 40 | 35° |

200 | 8 | 325 | 24 | 8 | 22 | 295 | 35 | 50 | 40 | 35° |

250 | 10 | 325 | 28 | 12 | 22 | 350 | 35 | 60 | 35 | 30° |

300 | 12 | 325 | 28 | 12 | 22 | 400 | 35 | 60 | 35 | 30° |