Flange Check Valve

Flange check valve are installed between flanges in pipelines. They are typically designed to fit specific pipe sizes and pressure ratings, and installation usually requires bolting the valve between two flanges using bolts and nuts.

Overview

Materials:

Flange check valves are commonly made of materials such as cast iron, carbon steel, stainless steel, and various alloys. The choice of material depends on factors such as the type of fluid, pressure, and temperature conditions.

Design:

Flange check valves typically have a disc or flap that swings or moves in response to the direction of flow. When fluid flows in the desired direction, the disc moves freely, allowing the fluid to pass through. However, if there is a reversal of flow, the disc quickly closes, preventing backflow.

Types:

There are various types of flange check valves, including swing check valves, tilting disc check valves, and piston check valves. Each type has its own advantages and is suitable for different applications.

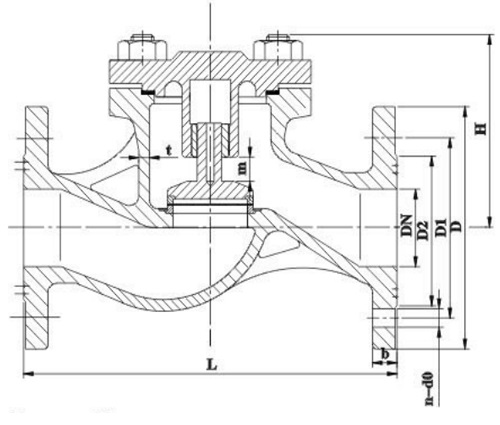

Drawing:

Elementary Dimensions | |||||||||||||||||

PN (Mpa) | DN (mm) | Frame dimension | Thickness | Flange | bolt | Lift Range | Weight kg | ||||||||||

I | J | H = | Hi | ||||||||||||||

A | B | A | B | B | D | Di | D2 | do | b | n | Th. | A | B | ||||

1.0 | 65 | 290 | 115 | 123 | 94 | 115 | 6 | 155 | 123 | 104 | 15 | 14 | 6 | M14 | 19 | 122 | 11.3 |

80 | 310 | 125 | 139 | 104 | 125 | 170 | 138 | 118 | 8 | 23 | 164 | 14.3 | |||||

100 | 350 | 150 | 160 | 117 | 135 | 190 | 158 | 138 | 28 | 24.6 | 22.7 | ||||||

125 | 400 | 175 | 185 | 129 | 155 | 7 | 215 | 183 | 164 | 10 | 35 | 37 | 30.4 | ||||

1.6 | 197 | 143 | 225 | 187 | 168 | 17 | 17 | M16 | 45.8 | 40.0 | |||||||

2.5 | 20 | 150 | 75 | 79 | 66 | 75 | 5 | 95 | 68 | 48 | 13 | 12 | 4 | M12 | 6 | 3.6 | 3.5 |

25 | 160 | 80 | 80 | 67 | 80 | 105 | 73 | 56 | 13 | 7 | 43 | 4.1 | |||||

32 | 180 | 85 | 85 | 68 | 85 | 115 | 83 | 64 | 15 | 6 | M14 | 9 | 5.0 | 4.8 | |||

40 | 200 | 90 | 88 | 76 | 90 | 125 | 93 | 74 | 14 | 12 | 63 | 6.0 | |||||

50 | 230 | 95 | 109 | 85 | 95 | 6 | 135 | 103 | 84 | 15 | 8.6 | 8.2 | |||||

65 | 290 | 115 | 123 | 94 | 115 | 7 | 170 | 132 | 110 | 17 | 17 | 8 | M16 | 19 | 133 | 11.5 | |

80 | 310 | 125 | 150 | 110 | 125 | 8 | 185 | 147 | 126 | 19 | 23 | 19.8 | 17.3 | ||||

100 | 350 | 150 | 155 | 118 | 135 | 205 | 167 | 146 | 10 | 28 | 303 | 25.7 | |||||