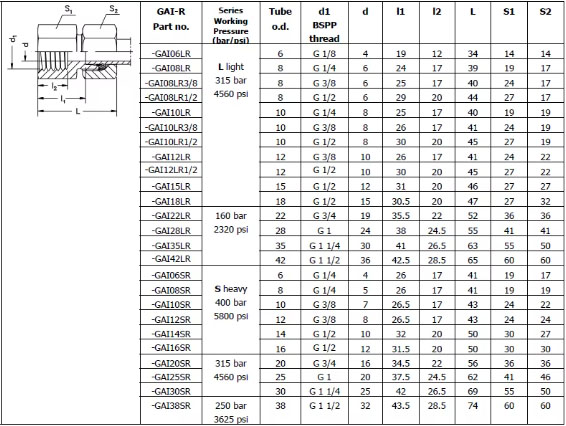

Female Stud Couplings

Material Stainless:Steel

Pressure:High Pressure

Thread Type:UNF/NPT/BSPT

Size:2 to 38 mm

Applicable media:Water, Gas, Air,etc

Installation:Sleeve Type

Connection:Female

Certification:CE,ISO

Overview

Production requirements:

1.Material selection: Straight threaded joints are usually made of stainless steel (such as 304 or 316 stainless steel). 304 stainless steel has good corrosion resistance, while 316 stainless steel has better corrosion resistance, especially in high-temperature environments. The selection of suitable materials depends on the specific usage environment and requirements.

2.Structural design: The structural design of straight threaded joints should take into account their purpose and connection method. The two end open close quick connector consists of a connector body, a one-way valve core, an outer sleeve, a steel ball, a spring, and a seal, ensuring the tightness and safety of the connection.

3.Processing and production: Processing and production of straight internal thread joints require precise mechanical processing techniques, including turning, milling, etc., to ensure the dimensional accuracy and surface quality of the joint. In addition, the internal thread form of the joint should be internal thread to meet different connection requirements.

4.Scope of application: Straight through internal thread joints are widely used in oil circuit connections and other fields. Their temperature resistance range is usually -30 to+80 ℃, and their pressure resistance can reach 29MPa, meeting the needs of various industrial applications.

5.Product features: The straight through internal thread joint has the characteristics of easy connection, good sealing, and durability, and is suitable for connecting various industrial pipeline systems, especially in situations where frequent disassembly or quick replacement is required.

Specifications: