Factors Affecting Water Seal Interface of Marine Centrifugal Separator

The water sealing interface in the principle of marine separator is a crucial concept. In the working process of the separator, after the oil-water mixture enters the interior of the separator, due to the action of gravity and centrifugal force, the oil and water will gradually stratify. And the water sealing interface is formed between the water phase and the oil phase, which plays a key isolation role. Through ingenious design and precise control, the water sealing interface can effectively prevent the oil phase from entering the water outlet, ensuring that only the purified water is discharged, and at the same time ensuring that the oil phase can be collected according to the established path. The formation and stable maintenance of this water sealing interface is an important basis for the marine separator to achieve efficient oil-water separation, which guarantees the smooth progress of the separation process and the reliability of the separation effect.

Overview

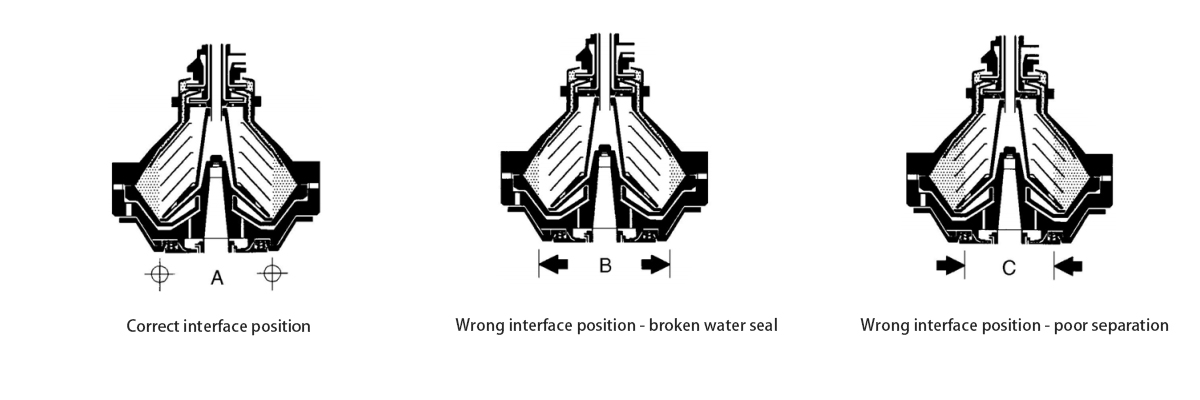

Position of the water sealing interface

In order to make the separator achieve the ideal separation effect, the water sealing interface must be maintained at the correct position, between the edge of the separation disc group and the outer edge of the top disc. If the interface moves beyond the outer edge of the top disc, the water sealing will be damaged and the oil will be discharged along with the water. If the interface is located within the edge of the separation disc group, it will cause very poor separation effect. The position of the interface is changed according to the pressure balance of the oil-water liquid phase in the oil separator, which is affected by multiple factors.

Several factors affecting the interface

Viscosity, density and flow rate of the oil

High density or high viscosity and high flow rate will make the oil/water interface closer to the edge of the separation drum than the oil with lower parameter values.

Specific gravity ring

Replacing with a specific gravity ring with a slightly larger aperture will cause the interface to move towards the edge of the separation drum. While a specific gravity ring with a smaller aperture will cause the interface to move closer to the center of the separation drum.

Excessive back pressure

At the oil outlet, high back pressure prevents the oil from being extracted. The internal oil level will move towards the center of the separation drum, and at the same time push the oil/water interface to move towards the edge of the separation drum. This will affect the interface to the wrong position and even damage the water seal.

Conclusion

The above is the entire content of this article. In the article, we have detailedly introduced to you the water seal interface of marine separator. We hope that through this article, it can help you choose the marine separator.

Finally, if you have the need for procurement, you are welcome to visit our marine oil separator homepage or contact us at any time! Thank you again for your browsing!