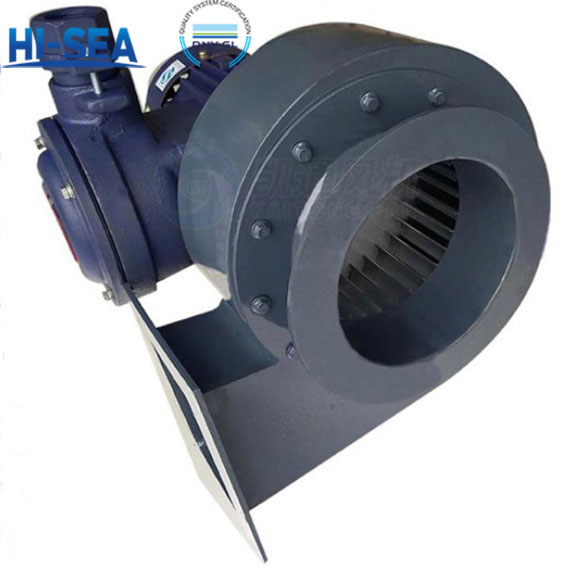

Explosion Proof Fan For Air Supply

Explosion Proof Fan For Air Supply is a mechanical device that relies on input mechanical energy to increase gas pressure and discharge gas. It is a passive fluid machinery. Centrifugal fans are widely used for ventilation, dust removal, and cooling in factories, mines, tunnels, cooling towers, vehicles, ships, and buildings; Ventilation and induced draft for boilers and industrial furnaces; Cooling and ventilation in air conditioning equipment and household appliances; Drying of grains and selection of wind tunnel sources, as well as inflation and propulsion of hovercraft.

Overview

Usage:

The usage characteristics of Explosion Proof Fan For Air Supply also include reducing the possibility of accumulation of explosive mixtures in hazardous areas, lowering the concentration and temperature of hazardous gases, providing good ventilation conditions, and keeping flammable and explosive mixed gases or vapors in a safe state.

Production Details:

Simulation testing: wind speed and pressure testing, vibration testing, noise testing, fluid simulation.

Technical advantage: All product designs use 3D modeling for work-piece interference testing and simulation operation.

Variable frequency explosion-proof motor: Explosion proof design, safe and reliable, the shell adopts a fully enclosed air-cooled structure and uses high mechanical strength materials.

Belt pulley: With high power transmission, simple structure, convenient installation and maintenance, low vibration and noise, and smooth operation.

Stainless steel impeller: Made of stainless steel material, it is corrosion-resistant, high-temperature resistant, high hardness, and not easily deformed. After strict dynamic balance calibration, it runs smoothly.

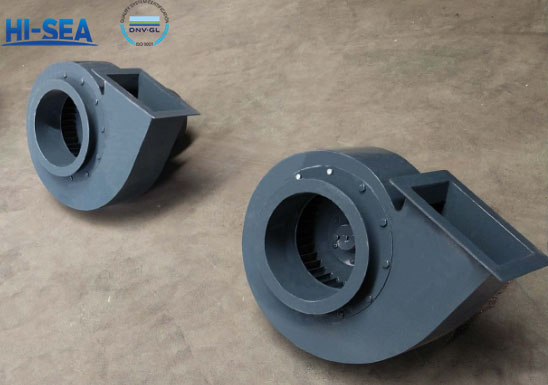

Display: