ESCO Dredging Cutter Teeth

Dredge Cutter Teeth can use on various types of dredging equipment. For example, cutter heads, dredging wheels and drag heads. There are several types and different sizes of dredger teeth. The shape, material and fixation system of dredge cutter teeth, combined with their strength and reliability make a significant contribution to improving production.

Overview

Design Innovations:

Optimized Geometry: ESCO designs its cutter teeth with optimized shapes to maximize cutting efficiency and reduce drag, which in turn can lower fuel consumption and increase productivity.

Self-Sharpening Profiles: Some ESCO teeth are designed to maintain their sharpness as they wear, providing consistent performance over time.

Interchangeable Systems: ESCO often incorporates interchangeable tooth systems, allowing for easy replacement and minimizing downtime during dredging operations.

Features

1. Various types of teeth like flare type, chisel type and pick type.

2. Flare type are used for peat, sand and soft clay

3. Narrow chisel type are applied in packed sand and firm clay

4. Teeth with pick points are used for rock

5. Special mounting geometry

6. Increased lifetime, decreased frequency and duration of maintenance.

7. Can be customized according to your requirements or can provide OEM services.

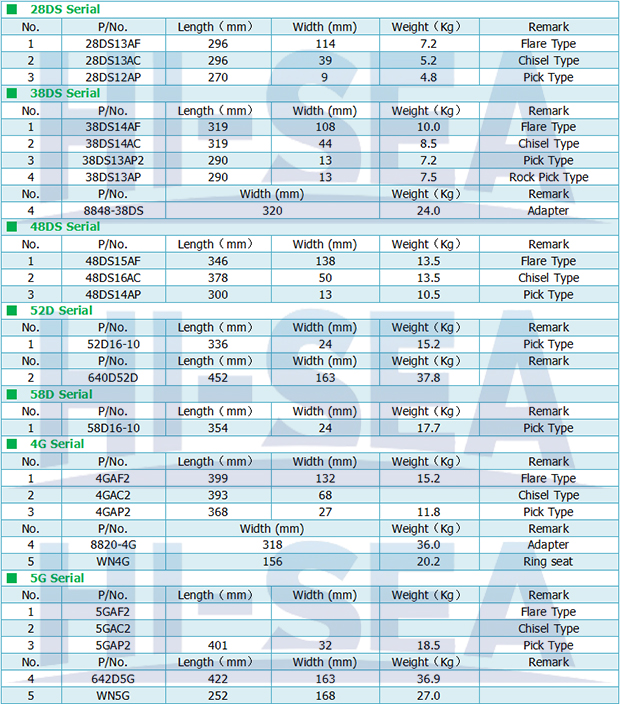

Specification

ESCO Dredging Cutter Teeth in Factory