Emulsified Oil Water Separator

The emulsified oil water separator is an environmental protection equipment used for separating, treating and purifying high-concentration emulsified oil sewage. The sewage containing high-concentration emulsified oil treated by our equipment has an oil content of less than 15ppm when discharged.

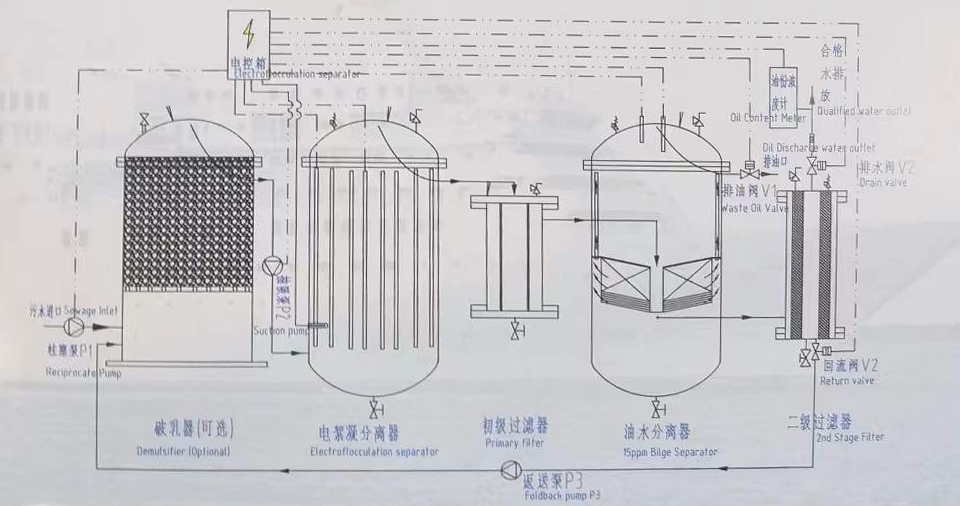

Our emulsified oil water separator is composed of a demulsifier (optional), an electrocoagulation separator, a primary filter, an oil water separator, a secondary filter, a plunger pump, a control pump, a control box, an oil content meter, pneumatic valves, etc.

In conclusion, it can effectively treat the oily sewage generated on ships and ensure that the discharge complies with international and domestic environmental protection regulations. It helps protect the mechanical equipment of ships.

If the bilge water generated by your ship cannot be well solved by the general oil water separator, I believe our emulsified oil water separator will provide you with another solution!

Overview

Principle Overview

The emulsified oil sewage first enters the solid-phase demulsifier (selected when the emulsified oil content is high), which destroys the electrical layer structure of water and oil to achieve the purpose of demulsification.

Then it enters the electrocoagulation reactor. Through a series of hydrolysis and polymerization reactions, substances such as hydroxyl complexes and hydroxides are generated. These generated substances have strong adsorption and cohesion capabilities and can interact with the oil droplets in the emulsified oil sewage, causing the oil droplets to lose stability, thereby promoting the aggregation and coagulation of emulsified oil.

The treated sewage then enters the primary filter to remove substances such as solid particles and flocs in the water.

The filtered oil-water mixture enters the oil-water separator. Through the polymerized inclined plate, the fine oil droplets are coalesced into large oil droplets that float up to the oil collection tank and are discharged when a certain liquid level is reached.

The water is discharged after being filtered by the secondary filter. An oil content meter is installed at the discharge port to detect the oil content in the discharged water. When the discharge standard is reached, the discharge valve is opened. When it exceeds the standard, the reflux valve is opened, and the discharged water is recycled for reprocessing to ensure that the discharged water quality meets the requirements.

Processing Flow Chart

Principle Drawing

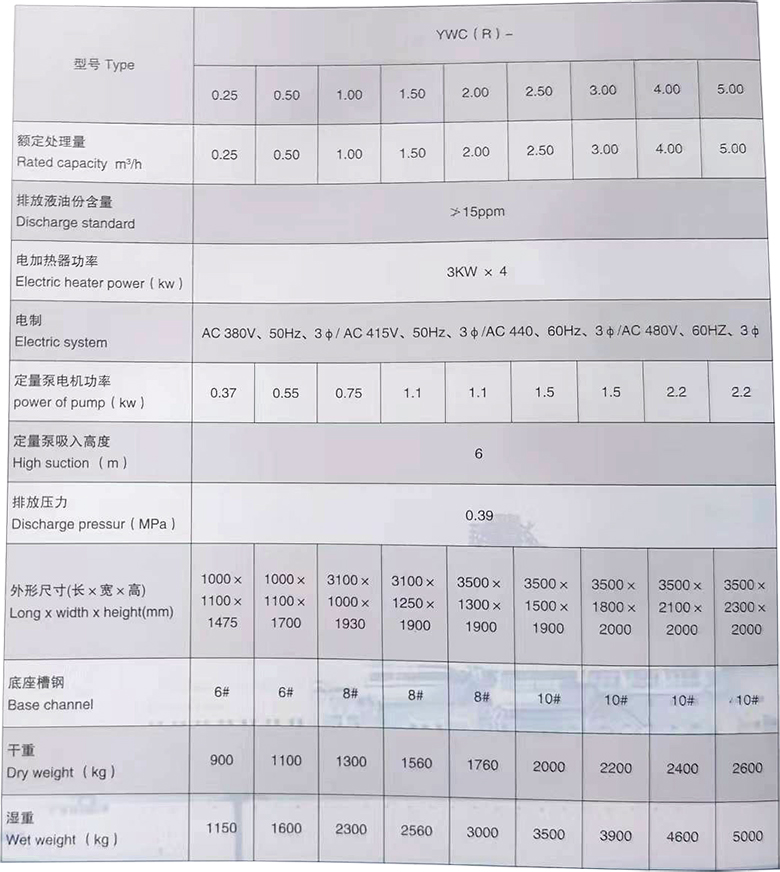

Technical Parameter

Conclusion

By browsing this article, we believe that you must have a certain understanding of emulsified oily water separator. If you have procurement needs or want to learn more about the details or parameters in depth, welcome to visit the homepage of our marine oily water separator, or contact us directly!