Dry-type Transformer

Dry-type transformers are transformers that use solid as insulation medium, and the core and windings are not immersed in insulating oil. Dry-type transformers are used in places with high safety and fire protection requirements, such as subways, airports, and high-rise buildings.

Overview

Standard & certificates

Conform to the standards of JB/T 9646-1999, GB 19212.5-2006, GB 1094.11-2007

Approved by CCS, ABS, DNV, etc.

Products we offer

SCB series dry-type power transformers

SG(B) series non-encapsulated H-class dry-type transformers

SCRBH15 amorphous alloy dry-type transformers

Dry-type rectifier transformers for hydrogen energy

Open-type dry-type transformers for energy storage

ZQSC(H)B series epoxy cast traction rectifier dry-type transformers

...

General product information

Rated capacity: 1kVA~2500kVA

Rated voltage: 690V, 660V, 440V, 380V, 220V

Rated frequency: 50Hz/60Hz

Connection group: Y, yn0, Y, d11, D, yn11, etc.

Protection level: IP00, IP20

Insulation level: Class B, Class F, Class H

Operating environment:

Altitude: ≤1000m

Ambient temperature: -10~+45℃

Relative humidity: ≤95% at 26℃

Usage environment: Indoor (please provide protection level when used outdoors)

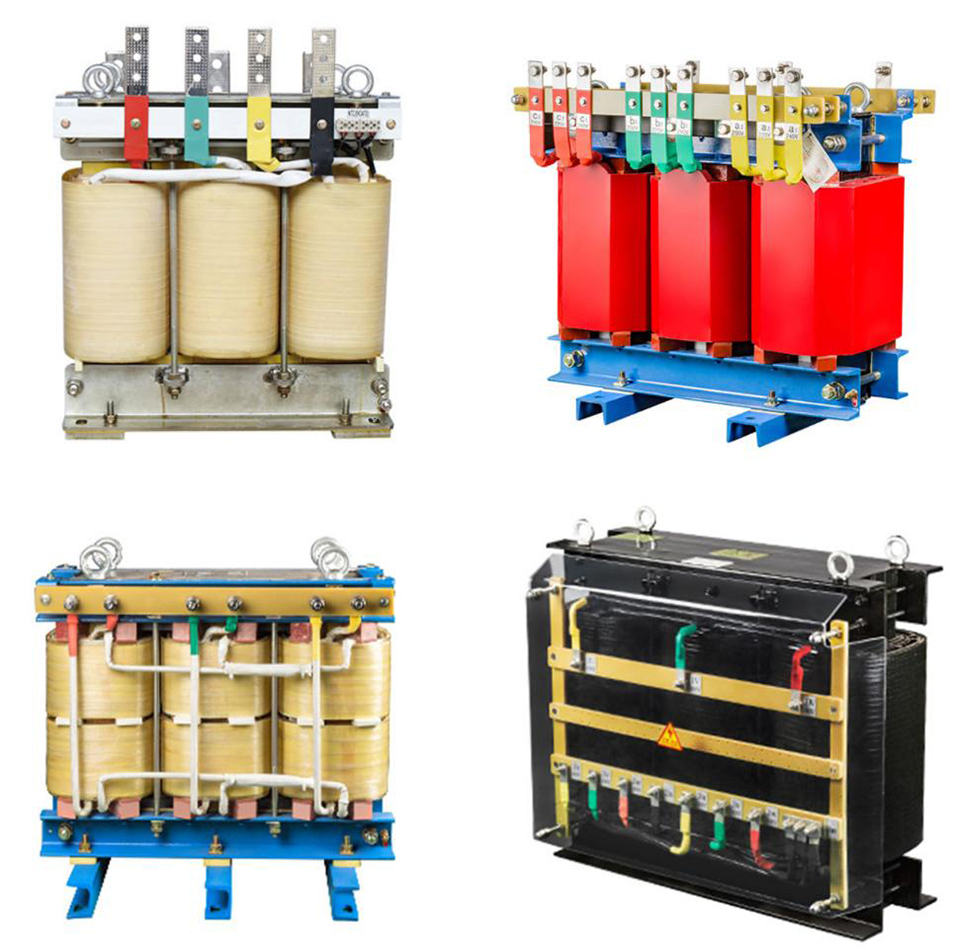

Product show

Product types

1. Impregnated air-insulated dry-type transformer: Winding conductor insulation and insulation structure materials are selected from insulation materials of different heat-resistant grades according to needs to make Class B, Class F and Class H insulation dry-type transformers.

2. Epoxy resin cast dry-type transformer: The insulation materials used are polyester resin and epoxy resin.

3. Wrap insulation dry-type transformer: Wrap insulation dry-type transformer is also a kind of resin insulation.

4. Composite insulation dry-type transformer:

(1) High-voltage winding adopts cast insulation, and low-voltage winding adopts impregnation insulation;

(2) High voltage adopts cast insulation, and low voltage adopts foil winding wound with copper foil or aluminum foil.

Features of dry-type transformer

1. Dry-type transformers can avoid the danger of fire and explosion of transformer oil due to failures during operation. Since the insulation materials of dry-type transformers are all flame-retardant materials, even if the transformer fails during operation and causes a fire or there is an external fire source, the fire will not be expanded.

2. Dry-type transformers will not have oil leakage problems like oil-immersed transformers, and there will be no problems such as transformer oil aging. Usually, the operation, maintenance and overhaul workload of dry-type power transformers is greatly reduced, and even maintenance-free.

3. Dry-type transformers are generally indoor devices, and can also be made outdoor for places with special requirements. It can be installed in the same room with the switch cabinet to reduce the installation area.

4. Since dry-type transformers are oil-free, they have fewer accessories, no oil storage cabinets, safety airways, a large number of valves and other components, and no sealing problems.

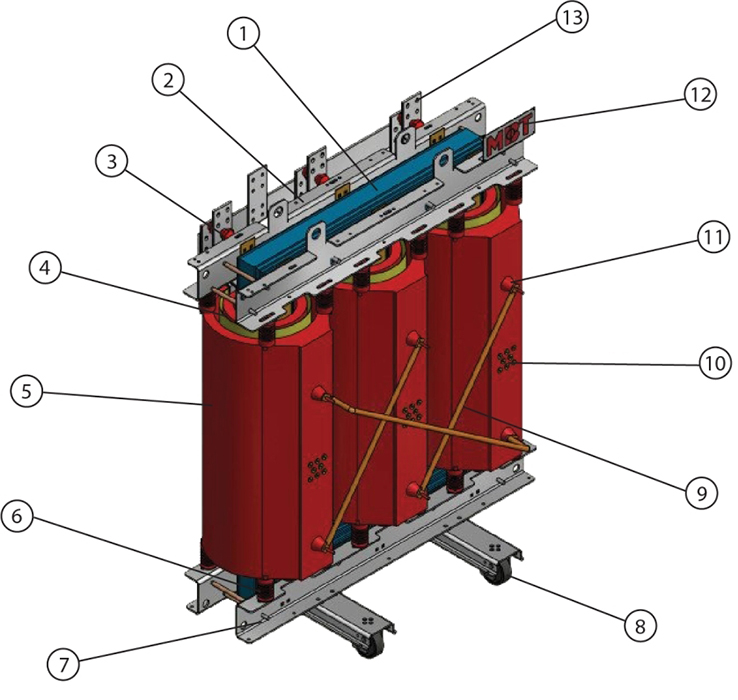

The structure of dry-type transformer

| |

1. Iron core | 8. wheels |

2. Core clamp | 9. HV connections tube |

3. bushing | 10. Tapping links |

4. LV winding | 11. HV connection cable |

5. Hv winding | 12. Logo MBT |

6. Support blocks | 13. LV terminal |

7. Core clamp | |