Dredging Ball Joint

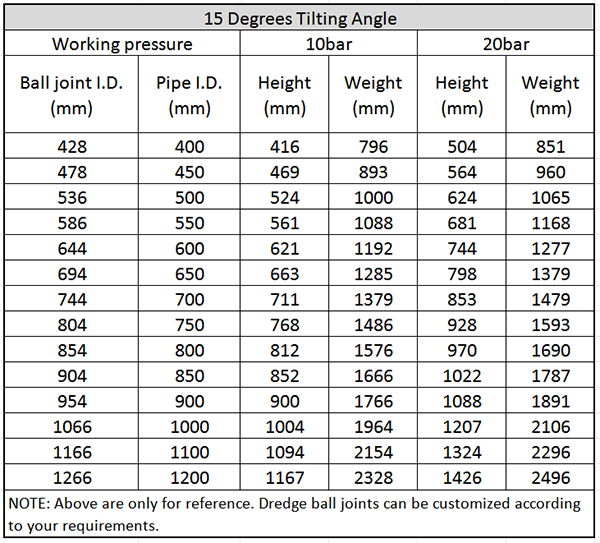

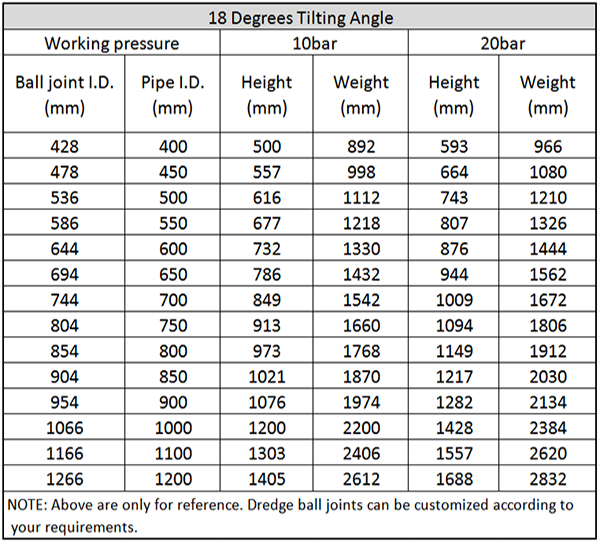

The dredging ball joint is a connection between two pipes used to transport a mixture of water and sand from the dredger to the discharge area. It can be used on a cutter suction dredger or a trailing suction hopper dredger. The dredging ball joints is designed to provide flexibility to the pipeline on dredgers in all round direction up to a limited angle. Its tilting angle can be from 15 to 18 degrees and duties from 10 bar to 20 bar. The pipe inner diameter is designed from 400mm to 1200mm.

Feature:

1. Sizes for pipe inner diameter: 400mm to 1200mm

2. Tilting angle: 15 degrees to 18 degrees

3. Easily replaceable liners.

4. Made for low, medium and high pressure.

5. It can be customized according to your specific needs.

Overview

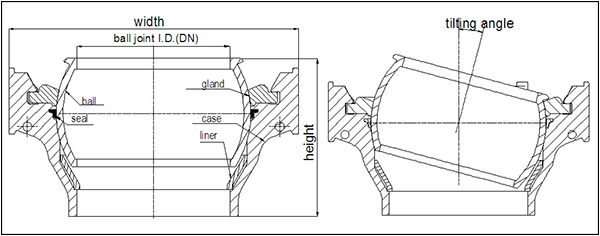

The dredging ball joint is a type of connection used in dredging operations, particularly in the assembly of pipeline systems used for transporting materials such as sand, silt, or slurry. The ball joint allows for flexibility and movement in the pipeline, accommodating changes in ground conditions, water currents, and other environmental factors. It consists of a spherical ball and socket design that allows for multi-directional movement and rotation, providing a flexible connection between pipeline sections. This flexibility helps to reduce stress and strain on the pipeline system, increasing its durability and longevity in challenging dredging environments.

Dredge ball joints type:

1. Tilting angle of 15 degrees:10bar,20bar and 30bar.

2. Tilting angle of 18 degrees:10bar,20bar and 30bar.

Materials:

CASE: ZG30Mn GLAND: ZG30Mn BALL: ZG30Mn

LINER: ZG30Mn or 30CrMoNi SEAL: NBR LOCK: Q345 or Q235

Drawing for Dredging Ball Joint

Main Technical Parameter