DIN PN16 Flange

DIN PN16 flange features include:

The nominal pressure is 16 bar (bar), equivalent to 1.6 MPa, which can ensure the safe operation of the pipeline system under certain pressure conditions;

With specific dimensions and construction standards to comply with DIN specifications. Its dimensions are usually specified in detail in the relevant standard documents;

There may be a variety of flange types, such as neck flat welded flange, plate flat welded flange, butt welded flange, etc.;

Commonly used materials include carbon steel, stainless steel, etc., to provide sufficient strength and corrosion resistance;

Various sealing surface forms, such as sudden surface (RF), full plane (FF), etc., to meet different sealing requirements;

Starting from DN200, flanges are different from PN10 in terms of aperture, number of holes, flange size and thickness;

Relatively convenient installation and maintenance, usually through bolted connection installation;

Widely used in various industrial pipeline systems, especially in occasions with high pressure requirements;

With a certain degree of interchangeability, PN16 flanges that meet DIN standards can be replaced with each other under the corresponding specifications.

Overview

How to maintain DIN PN16 flanges

1. Check regularly

Regularly inspect the flange connection for signs of leakage, corrosion, deformation or damage.

Check the tightening degree of the bolt to ensure that the bolt is evenly stressed to avoid loosening.

2.Clean

Remove dirt, debris and corrosion products from the surface of the flange and keep the surface clean.

For the case of corrosive media residue, timely cleaning and neutralization treatment.

3.Lubricate

Properly lubricate bolts and nuts to prevent rust and facilitate removal.

4. Anti-corrosion treatment

According to the use of the environment and the corrosion of the medium, take corresponding anti-corrosion measures, such as coating anti-corrosion coatings, the use of anti-corrosion gaskets.

5. Avoid overload

Ensure that the working pressure of the piping system does not exceed the rated pressure of the flange to avoid flange damage caused by overload.

6. Install and remove it correctly

When installing and removing flanges, follow the correct operation process and torque requirements to avoid damage caused by strong assembly or disassembly.

7. Replace the gasket regularly

Gaskets may age or fail after a period of use. Replace gaskets regularly to ensure sealing performance.

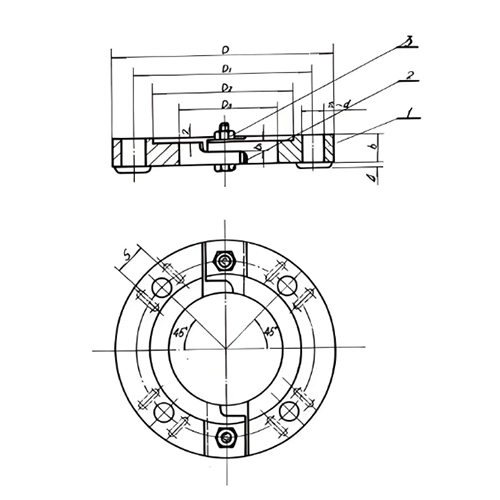

Drawing

Images of DIN PN16 Flange