Different Twistlocks on containers

Overview

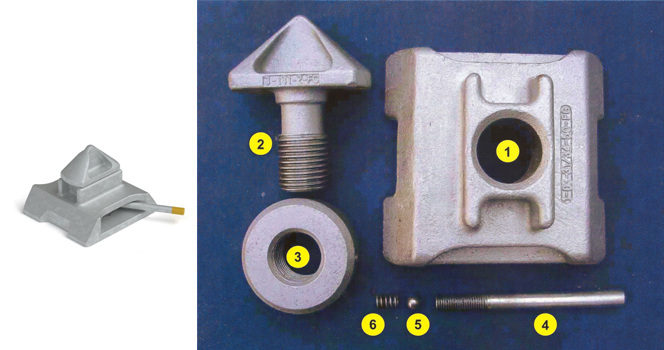

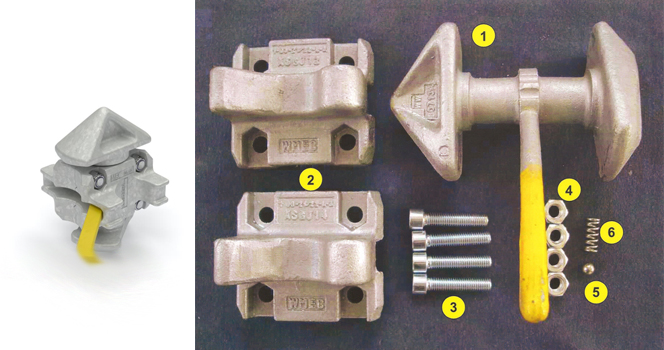

Manual Twistlocks:

The end of the twistlock is mushroom-shaped. When in use, the twistlock is first inserted into the bottom holes of the four corner castings of the container, and then the handle is pushed and twisted 90° to lock the container. Dovetail bottom twistlocks can only be used with dovetail bottom foundations.

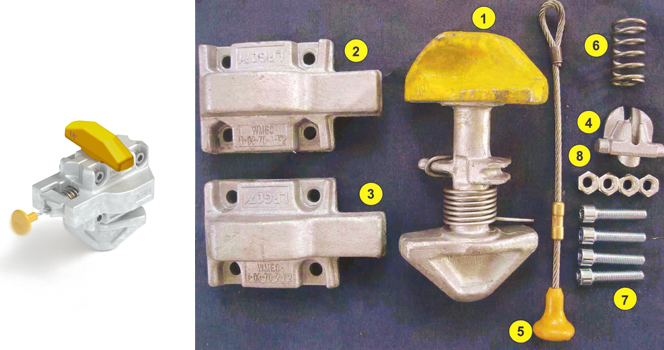

Semi-automatic Twistlocks:

During loading, when the container is lifted to a height equivalent to a person raising their arm, the semi-automatic twist lock is inserted from below into the corner casting of the container. Once the container is lifted onto the ship and aligned with the protruding base or another corner casting of the container, and the lock's automatic mechanism engages, securing the connection with the container. When unloading the container, the operator uses a control rod to pull out the lock pin, opening the twist lock and releasing the connection with the protruding base or another top corner casting of the container. The twist lock is then removed when the container is lowered to the terminal by the personnel.

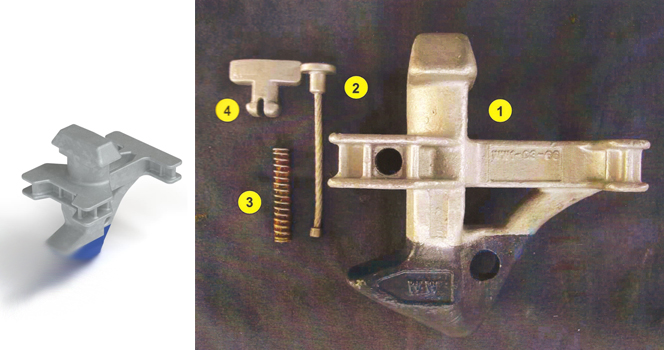

Fully Automatic Twistlocks:

One end of the twist lock is spiral-shaped. When the container's weight is applied to the spiral-shaped lock head, it generates a torque, causing the lock head to rotate automatically and secure the connection between containers. When the container is lifted, the twistlock unlocks under the force of a spring.

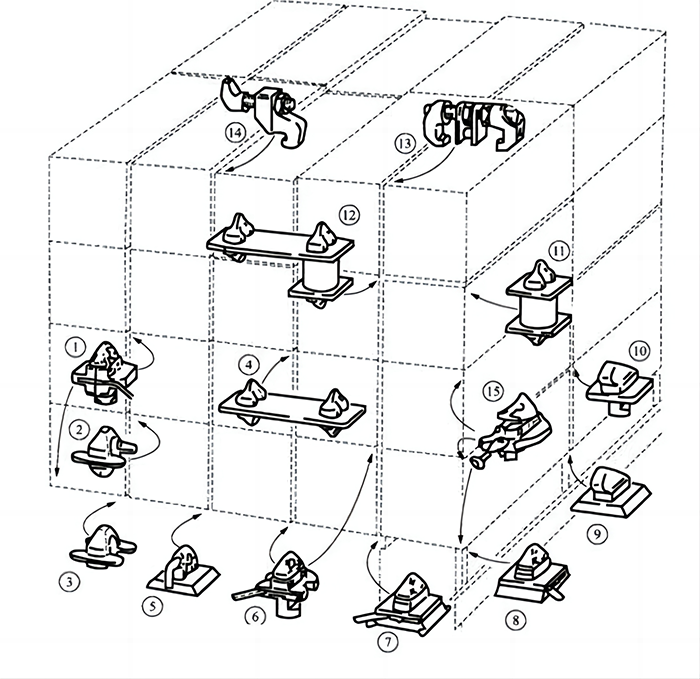

The positions of twistlocks and stackers

1:mid twistlock

2:stacking cone

3:bottom stacking cone

4:double stacking cone

5:bottom twistlock

6:flush bottom twistlock

7,8:dovetail bottom twistlock

9:automatic bottom twistlock

10:automatic mid twistlock

11:height compensator

12:bridge compensating stacking cone

13:bridge fitting

14:high-low container bridge fitting

15:semi-automatic twistlock