Differences Between Chain hoist and Wire Rope Hoist

Whether manual, electric, or pneumatic hoists, the commonly used sling materials for these lifting equipment are divided into two types: chain and wire rope. Both are made of metal but have different structures, leading to differences in application. Do you know which type of hoist offers the best value for money? After reading this article to understand the differences between chain hoists and wire rope hoists, you will no longer have this question.

Overview

Structural Differences between Chain and Wire Rope

A lifting chain consists of interconnected oval links. The material of the chain is usually alloy steel. Alloy steel has malleability. The alloy is subjected to high-temperature forging and quenching, bending, and welding. Throughout the process, the internal structure of the alloy steel remains undamaged, ensuring consistent molecular distances within the alloy steel, guaranteeing the uniform density of the lifting chain, and any damaged parts of the lifting chain are easily visible.

A wire rope is formed by wrapping small steel wires together. This process involves drawing, stranding to form multiple strands twisted together to form ropes, increasing the strength of the wire rope. When works, due to wear between the steel wires, the damages of the internal wires cannot be directly observed. You need wire rope testers to detect internal wire damage, which increases the difficulty of maintaining and servicing wire rope hoists.

Load Capacity

Both electric and manual hoists typically have a load capacity of up to 5 tons for single chain hoists. Due to its dense multi-strand steel wire structure, single wire rope hoists are usually designed with load capacities of up to 50 tons.

Durability and Speed

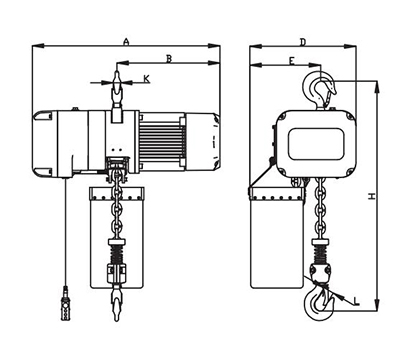

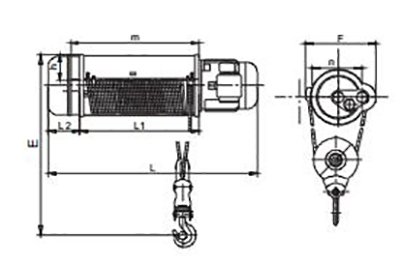

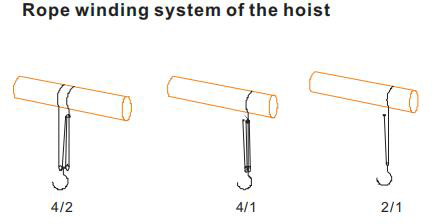

Chain hoists use an effective rope winding system where the chain passes through a single pulley, allowing for precise vertical lifting. Wire rope hoists use a different rope winding method. The wire rope winds around a single drum, and during operation, the wires may make slight lateral movement, naturally sliding into their position on the drum. By using multiple drums and combining the fed wire ropes (up to two sections) with pulleys, the lifting capacity and durability of wire rope hoists are maximized. However, due to the longer travel distance of the wire rope, the speed of lifting is reduced. Unlike wire rope hoists, chain hoists do not have as much flexibility in their rope winding method, resulting in faster lifting speeds, but due to the characteristics of their materials and structure, chains and other parts are easier to be wore than wire rope hoists.

Cost and Price

Chain hoists have a simple structure and rope winding system, and their components cheaper than wire rope hoists’. In general, chain hoists are typically cheaper than wire rope hoists. For example, in the market, the price of electric chain hoists ranges from $2000 to $10000. The price of electric wire rope hoists may range from $5000 to $100,000. However, unit cost is not the only factor to consider when purchasing, maintenance costs, service life, and actual application should also be considered. Wire rope hoists typically have higher maintenance costs than chain hoists. However, the service life of wire rope hoists can exceed 20 years, while chain electric hoists have a service life of about 10 years.

Application

As mentioned earlier, chain hoists have small load capacities, simple structures, and are easy to operate and carry, making them suitable for lifting and traction of small and lightweight goods. Wire rope hoists have higher load capacities and are suitable for lifting heavy goods or mechanical facilities.