CSG Series Vertical Centrifugal Pump

CSG type water pump using IS type centrifugal pump performance parameter, coaxial pump machine has the advantages of simple structure, in strict accordance with international standards of ISO2858and the new national standards for the design of successful energy efficient products is to replace IS type horizontal pump, type DL pump and conventional products centrifugal pump. Basic type, expanding type, A, B, C cutting type and so on more than 400 kinds of specifications. According to the flow medium and temperature difference, the design and manufacture of same parameters of pump hot water (200℃), chemical pumps, oil pumps, explosion-proof chemical pump.

Overview

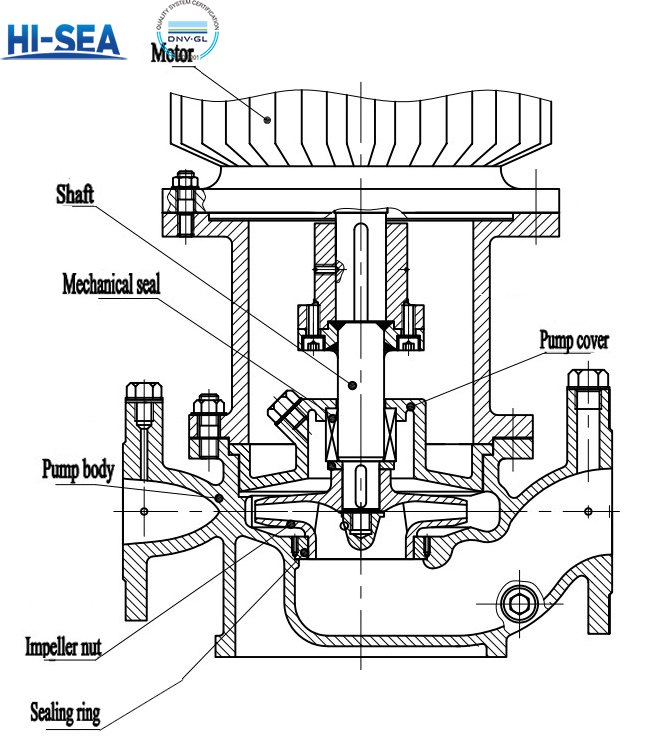

CSG Series Marine Vertical Centrifugal Pump Structure

Model Explanation CSG (R, H, B, BH)D、50-160 (I) A(B, C)

CSG— Single-stage single-inlet marine vertical centrifugal pump

R/H/B/BH— Hot-water pump/Chemical pump/Oil pump/Non-explosive chemical pump

D— Slow Speed of revolution

50— Inlet and outlet diameter 50 mm

160— Nominal diameter of impeller 160mm

I— Flow classification

A(B, C)— Impeller processed with 1(2, 3)cutting

Technical Parameters

Capacity | Head ( m ) | Motor Power | Speed | Voltage |

1.1 ~ 1740 (m³/h) | 7~ 180 ( m ) | 0.18 ~ 250( Kw ) | 1450/1800/2900/3500(r/min) | 380/440V |

CSG | 50HZ | 60HZ | 50HZ/60HZ | ||||||||

Type | Capacity (m3/h) | Head (m) | Speed (rpm) | Motor power (kW) | Weight (kg) | Capacity (m3/h) | Head (m) | Speed (rpm) | Motor power (kW) | (NPSH)r (m) | Efficiency (%) |

15-80 | 1.1 | 8.5 | 2900 | 0.18 | 17 | 1.3 | 12.2 | 3500 | 0.25 | 2.3 | 26 |

1.5 | 8 | 1.8 | 11.5 | 34 | |||||||

2 | 7 | 2.4 | 10.1 | 34 | |||||||

20-110 | 1.8 | 16 | 2900 | 0.37 | 25 | 2.2 | 23 | 3500 | 0.75 | 2.3 | 25 |

2.5 | 15 | 3 | 21.6 | 34 | |||||||

3.3 | 13.5 | 4 | 19.4 | 35 | |||||||

20-125 | 1.8 | 21 | 2900 | 0.75 | 35 | 2.2 | 30.2 | 3500 | 1.1 | 2.3 | 30 |

2.5 | 20 | 3 | 28.8 | ||||||||

3.3 | 18.6 | 4 | 26.8 | ||||||||

20-160 | 1.8 | 33 | 2900 | 1.1 | 29 | 2.2 | 47.5 | 3500 | 1.5 | 2.3 | 19 |

2.5 | 32 | 3 | 46.1 | 25 | |||||||

3.3 | 30 | 4 | 43.2 | 23 | |||||||

25-110 | 2.8 | 16 | 2900 | 0.55 | 26 | 3.4 | 23 | 3500 | 0.75 | 2.3 | 34 |

4 | 15 | 4.8 | 21.6 | 42 | |||||||

5.2 | 13.5 | 6.2 | 19.4 | 41 | |||||||

25-125 | 2.8 | 20.6 | 2900 | 0.75 | 28 | 3.4 | 29.7 | 3500 | 1.1 | 2.3 | 28 |

4 | 20 | 4.8 | 28.8 | 36 | |||||||

5.2 | 18 | 6.2 | 25.9 | 35 | |||||||

25-125A | 2.5 | 17 | 2900 | 0.75 | 27 | 3 | 24.5 | 3500 | 1.1 | 2.3 | 35 |

3.6 | 16 | 4.3 | 23 | ||||||||

4.6 | 14.4 | 5.5 | 20.7 | ||||||||

130 | 42 | 156 | 60.5 | 73 | |||||||

200-500(I)B | 242 | 63.8 | 1450 | 90 | 1050 | 290.4 | 91.9 | 1800 | 132 | 4 | 74 |

346 | 60 | 415.2 | 86.4 | 76 | |||||||

450 | 52.5 | 540 | 75.6 | 74 | |||||||

200-500(I)C | 224 | 53.2 | 1450 | 75 | 906 | 268.8 | 76.6 | 1800 | 110 | 4 | 73 |

320 | 50 | 384 | 72 | 75 | |||||||

416 | 42.8 | 499.2 | 61.6 | 73 | |||||||

250-250 | 350 | 22 | 1450 | 45 | 620 | 420 | 31.7 | 1800 | 75 | 5 | 78 |

550 | 20 | 660 | 28.8 | 82 | |||||||

650 | 16 | 780 | 23 | 81 | |||||||

250-250A | 300 | 18.3 | 1450 | 37 | 550 | 360 | 26.4 | 1800 | 55 | 5 | 76 |

500 | 17 | 600 | 24.5 | 80 | |||||||

600 | 14 | 720 | 20.2 | 80 | |||||||

250-235 | 300 | 14 | 1450 | 22 | 410 | 360 | 20.2 | 1800 | 37 | 4.5 | 73 |

500 | 12.5 | 600 | 18 | 78 | |||||||

600 | 11 | 720 | 15.8 | 70 | |||||||

250-300 | 300 | 22 | 1450 | 37 | 550 | 360 | 31.7 | 1800 | 55 | 4.5 | 78 |

500 | 20 | 600 | 28.8 | ||||||||

600 | 16 | 720 | 23 | ||||||||

300-235B | 420 | 14.3 | 1450 | 37 | 925 | 504 | 20.6 | 1800 | 55 | 5 | 73 |

540 | 12.8 | 648 | 18.4 | 78 | |||||||

650 | 10.5 | 780 | 15.1 | 70 | |||||||

300-235(I) | 718 | 44.6 | 1450 | 160 | 1450 | 861.6 | 64.2 | 1800 | 250 | 5.5 | 82 |

1080 | 40 | 1296 | 57.6 | ||||||||

1345 | 34.6 | 1614 | 49.8 | ||||||||

300-480B | 400 | 24 | 980 | 55 | 1180 | 480 | 34.6 | 980 | 90 | 5 | 77 |

540 | 21 | 648 | 30.2 | 79 | |||||||

650 | 17 | 780 | 24.5 | 78 | |||||||

350-300 | 600 | 22.5 | 1450 | 75 | 1230 | 720 | 32.4 | 1800 | 110 | 4.5 | 79 |

800 | 20 | 960 | 28.8 | 82 | |||||||

960 | 17.5 | 1152 | 25.2 | 71 | |||||||

350-315 | 480 | 35 | 1450 | 90 | 1650 | 576 | 50.4 | 1800 | 132 | 4.5 | 80 |

800 | 32 | 960 | 46.1 | 84 | |||||||

960 | 37 | 1152 | 53.3 | 81 | |||||||

350-400 | 600 | 55 | 1450 | 160 | 1950 | 720 | 79.2 | 1800 | 250 | 4.5 | 77 |

800 | 50 | 960 | 72 | 83 | |||||||

960 | 45.5 | 1152 | 65.5 | 80 | |||||||

400-300 | 820 | 23 | 1450 | 90 | 1570 | 984 | 33.1 | 1800 | 132 | 6 | 78 |

1080 | 20 | 1296 | 28.8 | ||||||||

1300 | 16 | 1560 | 23 | ||||||||

400-315 | 820 | 36.5 | 1450 | 132 | 1880 | 984 | 52.6 | 1800 | 200 | 6 | 78 |

1080 | 32 | 1296 | 46.1 | ||||||||

1300 | 27 | 1560 | 38.9 | ||||||||

500-300 | 1000 | 23 | 1450 | 110 | 1800 | 1200 | 33.1 | 1800 | 160 | 6 | 80 |

1200 | 20 | 1440 | 28.8 | ||||||||

1450 | 16 | 1740 | 23 | ||||||||

500-315 | 1000 | 34.5 | 1450 | 160 | 2070 | 1200 | 49.7 | 1800 | 250 | 6 | 78 |

1200 | 32 | 1440 | 46.1 | ||||||||

1450 | 27 | 1740 | 38.9 | ||||||||

The above parameters are for reference only. Please contact us for specific parameters. | |||||||||||

CSG Series Marine Vertical Centrifugal Pump in Factory

.jpg)

.jpg)