CPT-130C Table Model Marine Compass

Overview

Adopted certification: CCS

Features

Small in volume, light in weight, high price performance.

Reasonable construction, good corrosion resistance.

Stable in magnetism, reliable in operation and high in sensitivity.

Durable magnetic materials and long service life.

Accurate direction and high precision.

Specification & dimension

Project | Unit | Data |

Dial Diameter | mm | φ130 |

Dial graduation | 1° | 0°~360°1°for each grid |

Lighting power supply | V | DC 24V |

Outline Dimension | mm | 330×200×270 |

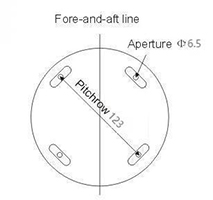

Installation Dimension | mm | Pitchrow φ123 Aperture φ6.5 |

Compass Net Weight | Kg | 3kg |

Technical data

Project | Data |

Card diameter | ф130mm |

Graduation | 1°(0~360°) |

Use temperature | -20~+60℃ |

Direction error | ≤1.5° |

Swing semi-period | ≥5.37S |

Friction error | ≤0.24° |

The main semicircular deviation correction of energy | 1°~45° |

Quadrant deviation correction | 0.5°~7° |

Illumination | DC24V |

Overall dimensions | 330*200*270 mm |

Carton size | 450*290*430mm |

Installation dimensions | pitchrow123 apertureф6.5 |

Net weight | About 3 Kg |

Base installation size

Maintenance

To ensure the magnetic compass installed on board could work normally all the time,the ship driver should often check the magnetic compass to confirm if all its parts are in good condition, whether its directional performance is good and could work normally.

Termly inspect friction deviation and semi-period, if the deviation is bigger, the compass should be sent to the related repair dept or factory to replace jewel or pivot.

Termly measure self heterodyne of the compass, pay attention to the change of self heterodyne. In normal condition, correct once half a year to one year.

Often do cleaning work better, especially pay attention to termly oiling the bearing therefore the compass will be in good working environment.

If the bubbles happened in the compass bowl, the user may open the inject hole and pour the spare compass liquid into the bowl. Do not add other liquid into the bowl to avoid the coating of the compass desquamated.