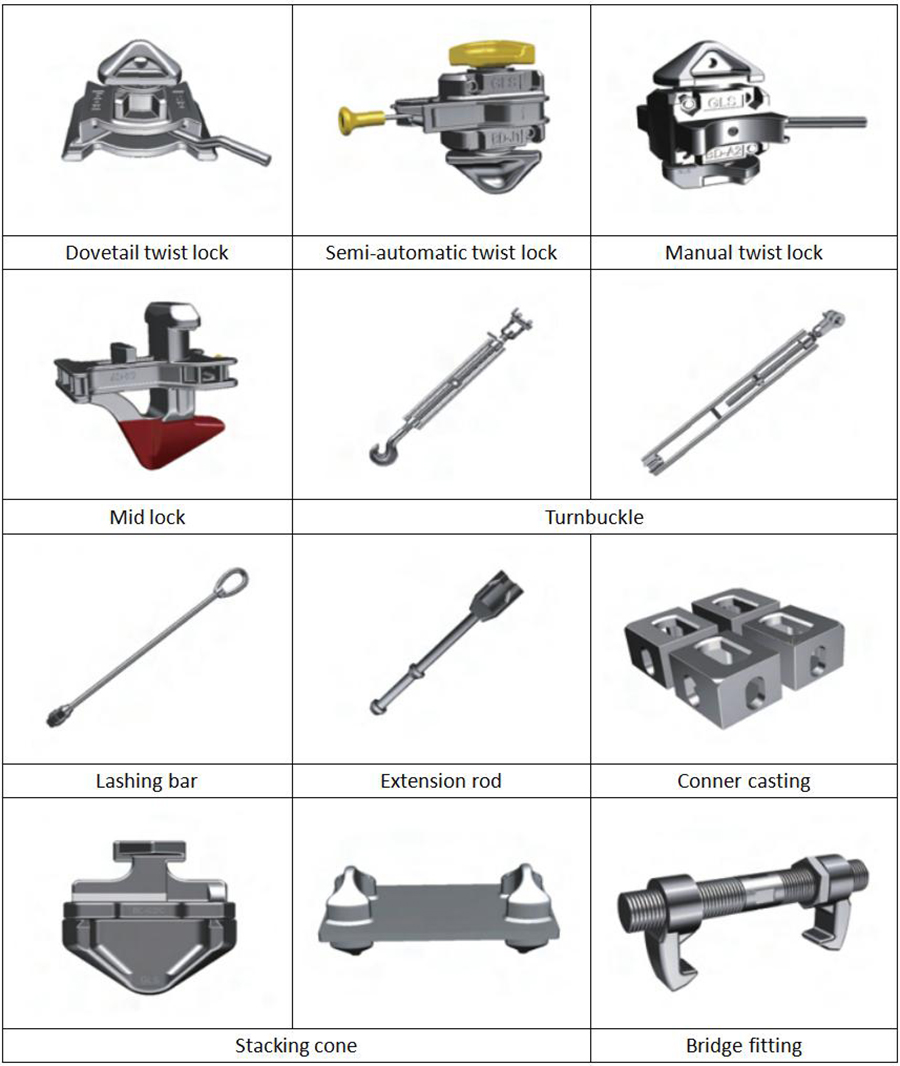

Container Loose Fittings

Loose fittings in maritime contexts are adjustable components designed for flexibility and ease of maintenance. Examples include turnbuckles, twistlocks, and lashing bars, allowing for adjustments or removals to accommodate changes, repairs, or replacements as needed on ships and boats, ensuring the safety of containers on the sea. All the container loose fittings conform to the standards of GB/T 11577-2010 and ISO, the quality is guaranteed.

Overview

Function details of different loose fittings

Twistlock: A twistlock is a device used to securely connect shipping containers, enabling efficient stacking and interlocking during cargo transportation, ensuring stability and preventing shifting at sea.

Stacker(stacking cone): A stacker is a handling equipment commonly used in warehouses and ports to vertically organize and transport palletized goods, contributing to efficient storage and logistics operations.

Bridge fitting: A bridge fitting is a structural component that provides a connection point for various maritime structures or equipment, ensuring stability and support on ships or offshore platforms.

Pressure element: A pressure element is a component designed to exert force or pressure within a system, often used in hydraulic or mechanical systems for specific functions such as sealing or controlling movement.

Lashing rod: A lashing rod is a robust bar or rod used in cargo securing to provide tension and prevent movement of goods, enhancing safety during transportation by sea or other modes.

Turnbuckles: Turnbuckles are adjustable devices used in maritime applications to regulate tension in ropes or cables, facilitating flexible and secure fastening, commonly employed for various purposes, including securing cargo and adjusting rigging.

Categories

Position

The Positions of Container Securing Fittings on a Vessel

Inspection of loose fittings

All equipment should be inspected for deformation and damage before being used again. If there is difficulty in rotation, check the internal conditions and restore flexibility.

If cracks appear in the main body, immediate replacement is necessary, and repair by welding should not be employed.

Structural damage to twist locks and bridge fittings may result from rough handling at loading and unloading ports. Such handling can also cause damage to other components. It is recommended to collect these parts in appropriate packages or boxes and then lower them onto the deck to avoid losses from improper operations.

Rust spots should be treated with anti-rust paint. If there is slight corrosion that does not affect functionality, no repair is necessary.

Regularly lubricate rotating and moving parts to maintain smooth operation.