Classification of Zinc Anodes

Zinc anodes are categorized based on their form, application, and composition. These classifications help in selecting the appropriate anode type for specific corrosion protection needs.

Overview

Introduction

Selecting the correct zinc anode is crucial for effective and economical cathodic protection. This guide categorizes zinc anodes from multiple perspectives to help you match the product to your specific environment, structure, and design requirements.

1. By Chemical Composition

Zinc-Aluminium-Cadmium Anodes (Type I & II): Offer enhanced electrochemical performance. Important: Contain cadmium; prior approval from the end-user is required due to environmental regulations. Maximum service temperature: 50°C.

Pure Zinc Anodes (Type III): The standard choice for most applications, known for their reliability and stable potential.

2. By Application Field (With Hisea Product Links)

This is the most practical way to start your selection. Choose based on what you need to protect:

For Ship Hulls: Click

For Ballast & Liquid Tanks: Click

For Harbour & Offshore Engineering: Click

For Seawater Cooling Systems: Click

For Storage Tanks & Buried Pipelines: Click

3. By Structural Type (How it's Attached)

Single/Double-Iron Foot Flat-Welded Anodes: For direct welding to large, flat surfaces.

Bolted Connection Anodes: For easier installation and replacement where welding is not feasible.

Disc Anodes: For specific fixtures or confined spaces.

Strip (Ribbon) Anodes: For long-distance, continuous protection or in narrow spaces.

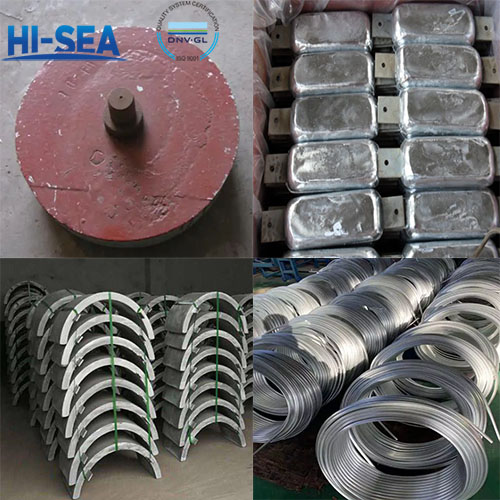

4. By Shape

Block Anodes: General purpose, high mass.

Bracelet Anodes: For pipelines, encircling the pipe.

Rod Anodes: For deep well groundbeds or inserted applications.

Disc & Custom Shapes: For specialized requirements.

Pictures of Zinc Anodes