Classification of Marine Air Compressors

Classified by structural type: V-type, W-type, or upright type

Classified by cooling method: marine air-cooled air compressor, marine water-cooled air compressor

Classified by rated pressure: Low-Pressure Air Compressor, Medium Pressure Air Compressor, and High-Pressure Air Compressor

Classified by the working principle: reciprocating air compressors, screw compressors, and centrifugal air compressors

Overview

1. Classification by structural type: Marine air compressors are divided into V-shaped, W-shaped, or upright structural types without cross heads.

2. Classification by cooling method:

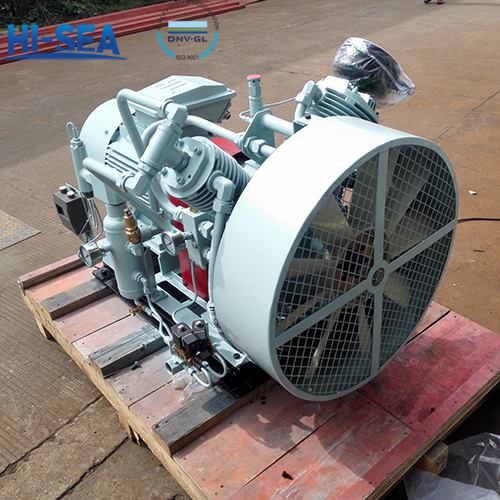

Marine air-cooled air compressor: uses air flow to remove the heat generated during the compression process.

Marine water-cooled air compressor: utilizes cooling water circulation to remove the heat generated during the compression process.

3. Classified by rated exhaust pressure:

Low pressure air compressor: The discharge pressure is generally between 0.2-1MPa.

Medium Pressure Air Compressor: The discharge pressure is generally between 1 and 10 MPa.

High Pressure Air Compressor: The air pressure is generally between 10 and 100 MPa.

4. Classification according to working principle:

Reciprocating Air Compressor: The piston in the cylinder sucks in and compresses during its stroke.

Screw Compressor: Air compression is carried out using two spiral rotors that mesh with each other.

Centrifugal Air Compressor: compresses air by the centrifugal force generated by the high-speed rotating impeller.

Vane Compressor: uses the sliding blades on the rotor to form multiple chambers on the inner wall of the stator for air compression.

Scroll Compressor: Air compression is achieved by the interaction between a fixed vortex plate and a moving vortex plate.

5. According to the principle of compressed gas, air compressors are classified into two categories: volumetric and velocity compressors

Generally, commercial diesel engine ships are equipped with 2-3 micro or small, medium pressure, water-cooled two-stage piston air compressors. The maximum working pressure of the main air cylinder is about 3MPa (the starting air pressure of the diesel engine cannot be lower than 1.5MPa), while other auxiliary gases with lower pressure, such as air whistle and control air, are supplied by the main air cylinder after being depressurized by the pressure reducing valve.

For more marine air compressor information, please click here.