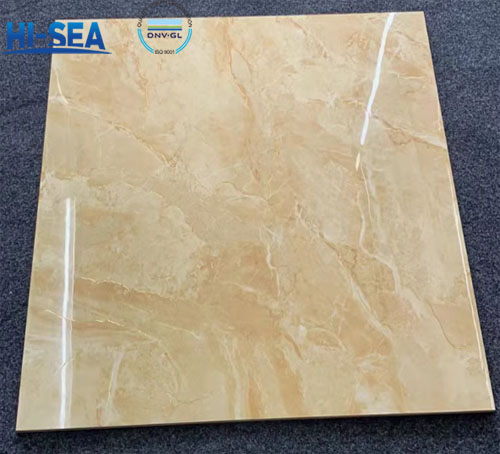

Ceramic Tile

Molding points: dry compression molding bricks, extrusion molding bricks, plastic molding bricks.

Burning composition: oxidizing tiles, reducing tiles.

Glaze: Glazed brick, unglazed brick.

Water absorption rate: porcelain tile, stoneware tile, fine stoneware tile, stoneware tile, ceramic tile.

Polished tiles, antique tiles, ceramic tiles, glazed, crystallized tiles, microcrystalline stone, split tiles, square tiles (cultural tiles).

Production process: printed tiles, polished tiles, speckled tiles, crystal tiles, unglazed tiles.

Overview

Testing:

Size: The size of the product is the same, which can save the construction time and is neat and beautiful.

Water absorption: the lower the water absorption rate, the better the degree of glass, the better the physical and chemical properties of the product, the less likely to be due to climate change, thermal expansion and contraction and cracking or peeling.

Flatness: Good flatness of the tiles, the surface does not bend, not warped, easy to construct, the ground is flat after construction.

Strength: High flexural strength, good abrasion resistance and resistance to heavy pressure, not easy to wear and tear, long-lasting, suitable for public places.

Color difference: The tiles will be placed flat on the floor, arranged in a square meter, three meters away to see whether there are different shades of color or can not be articulated, resulting in aesthetic obstacles.

Picture:

Size | ||

300*300mm | 300*600mm | 400*400mm |

400*800mm | 600*600mm | 800*800mm |

600*1200mm | 750*1500mm | 900*1800mm |