CCS marine screw air compressor

CCS marine screw air compressor is a compressed air equipment designed specifically for marine applications, certified by China Classification Society (CCS), and in compliance with relevant marine standards and specifications. It is mainly used for various pneumatic equipment and systems on ships, such as starting air, control air, and instrument air.

Overview

The working principle of CCS marine screw air compressors is similar to other screw air compressors, which suck in, compress, and discharge air through a pair of rotating screws. Its core components include the screw compressor host, drive motor, air filter, oil separator, cooling system, and control system.

Technical requirement

1. The air compressor should have a pressure gauge indicating, which can have waterproof or night light display function as needed.

2. After each stage of compression, the air compressor should be equipped with a safety valve, which should act sensitively and reliably. The opening pressure of the inter stage safety valve should not exceed 1.2 times the maximum working pressure of the stage, and the opening pressure of the final stage safety valve should not exceed 1.1 times the rated exhaust pressure.

3. The air compressor should be equipped with an automatic flow adjustment device to meet the user's requirements for flow changes.

4. The suction port of the air compressor should be equipped with an air filter.

5. The exhaust side of the air compressor should be equipped with an oil and gas separator.

6. The casing, exhaust end cover, exhaust chamber, and oil pump body of the air compressor should be subjected to a water pressure test at a maximum working pressure of 1.5 times.

When the air compressor is equipped with a speed increase box, the speed increase box should undergo a kerosene leakage test.

8. The rotor of the air compressor should undergo a dynamic balance test.

The vibration intensity of the air compressor should not exceed 7.1mm/s.

10. The high-temperature exhaust pipe of the air compressor should be equipped with insulation baffles or other appropriate insulation measures to ensure that the temperature of the parts that personnel may come into contact with does not exceed 60 ℃.

11. The air compressor can be equipped with the following automatic control performance, and all self-control components should be sensitive and reliable:

(1) Automatic start stop

(2) Automatic unloading

(3) Automatic unloading

(4) Gas, oil, and water pressure monitoring

(5) Gas, oil, and water temperature monitoring

Main characteristics

The main components and standard parts have undergone special process treatment, with good corrosion resistance, low power, low noise, compact structure, small volume, light weight, beautiful appearance, smooth operation, and convenient installation. They are mainly used for ships.

Suitable for various small and medium-sized vessels such as destroyers, patrol ships, oil boats, and landing craft.

Compact structure, small size, low noise, low vibration, low energy consumption, stable and reliable operation Equipped with automatic control and protection functions. Introducing German technology and obtaining ship type approval.

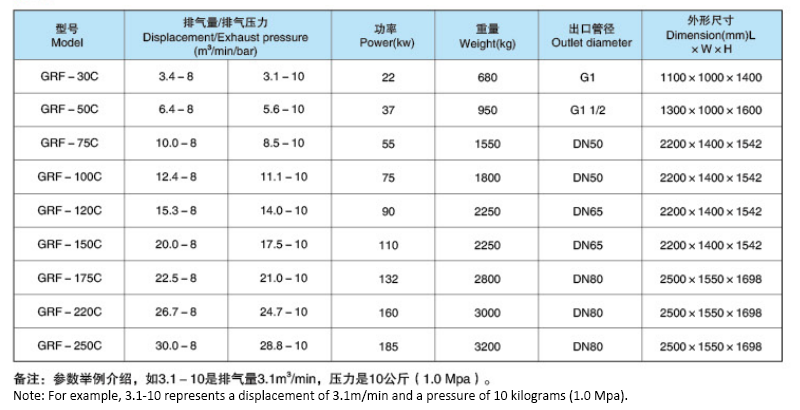

Main parameters