Cast Iron Check Valves

Cast Iron Check Valve is a type of non-return valve used in pipelines to prevent backflow of fluid. It operates automatically, allowing fluid to flow in one direction while closing to stop reverse flow. Cast iron is used for its durability and resistance to wear and corrosion, making these valves suitable for various applications, including water supply, HVAC systems, and marine environments.

Overview

Connection Type:

These valves often come with flanged ends for easy installation and maintenance. Flanges allow for secure attachment to piping systems.

Design:

They usually feature a swing-type design, where a disc swings on a hinge or pivot to allow flow in one direction while preventing reverse flow when the flow stops or changes direction.

Size Range:

Marine cast iron check valves are available in various sizes to accommodate different flow rates and system requirements commonly found on ships and other marine vessels.

Pressure Rating:

They are designed to withstand specific pressure ratings, ensuring reliable operation under varying pressure conditions within marine systems.

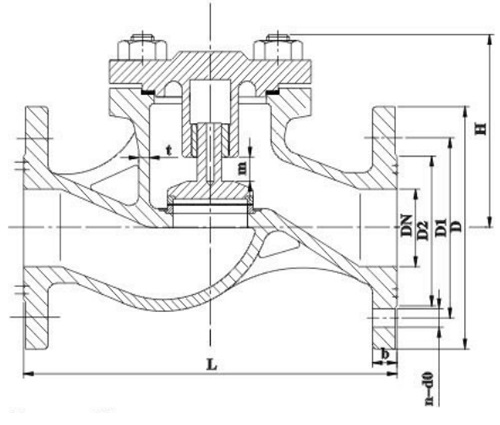

Drawing:

Elementary Dimensions | |||||||||||||||||

PN (Mpa) | DN (mm) | Frame dimension | Thickness | Flange | bolt | Lift Range | Weight kg | ||||||||||

I | J | H = | Hi | ||||||||||||||

A | B | A | B | B | D | Di | D2 | do | b | n | Th. | A | B | ||||

1.0 | 65 | 290 | 115 | 123 | 94 | 115 | 6 | 155 | 123 | 104 | 15 | 14 | 6 | M14 | 19 | 122 | 11.3 |

80 | 310 | 125 | 139 | 104 | 125 | 170 | 138 | 118 | 8 | 23 | 164 | 14.3 | |||||

100 | 350 | 150 | 160 | 117 | 135 | 190 | 158 | 138 | 28 | 24.6 | 22.7 | ||||||

125 | 400 | 175 | 185 | 129 | 155 | 7 | 215 | 183 | 164 | 10 | 35 | 37 | 30.4 | ||||

1.6 | 197 | 143 | 225 | 187 | 168 | 17 | 17 | M16 | 45.8 | 40.0 | |||||||

2.5 | 20 | 150 | 75 | 79 | 66 | 75 | 5 | 95 | 68 | 48 | 13 | 12 | 4 | M12 | 6 | 3.6 | 3.5 |

25 | 160 | 80 | 80 | 67 | 80 | 105 | 73 | 56 | 13 | 7 | 43 | 4.1 | |||||

32 | 180 | 85 | 85 | 68 | 85 | 115 | 83 | 64 | 15 | 6 | M14 | 9 | 5.0 | 4.8 | |||

40 | 200 | 90 | 88 | 76 | 90 | 125 | 93 | 74 | 14 | 12 | 63 | 6.0 | |||||

50 | 230 | 95 | 109 | 85 | 95 | 6 | 135 | 103 | 84 | 15 | 8.6 | 8.2 | |||||

65 | 290 | 115 | 123 | 94 | 115 | 7 | 170 | 132 | 110 | 17 | 17 | 8 | M16 | 19 | 133 | 11.5 | |

80 | 310 | 125 | 150 | 110 | 125 | 8 | 185 | 147 | 126 | 19 | 23 | 19.8 | 17.3 | ||||

100 | 350 | 150 | 155 | 118 | 135 | 205 | 167 | 146 | 10 | 28 | 303 | 25.7 | |||||