Cap Nuts

The nut of the sleeve type joint is a key component to ensure tight and safe pipeline connection, and its design and material selection directly affect the reliability of the connection and the safety of the system.

Overview

Application:

The nut plays a role in fixing and connecting. When two pipes are inserted into the sleeve, the sleeve will undergo elastic deformation under external force, fixing the two pipes together. At the same time, the elasticity of the card sleeve can also play a sealing role, preventing fluid leakage. When the nut is tightened, it will fix the sleeve on the pipe to ensure the firmness and stability of the connection. The advantage of sleeve type connectors is that they are easy to install, can be quickly connected and disassembled, and can withstand high temperatures and pressures, making them suitable for transporting various fluid media.

Purchase Guide:

1.Standard and Model: The selection of nuts for sleeve type joints should be based on the specific model of the joint and the required technical standards.

2.Material and performance: The material and performance of the nut are also factors that need to be considered when selecting.

3.Size and compatibility: Ensure that the size of the selected nut matches the size of the joint body to avoid problems such as poor sealing or inability to fix due to size mismatch.

4.International standards and compatibility: For joints that need to be used in international projects, consider using nuts that comply with international standards (such as ISO standards) to ensure compatibility and interchangeability.

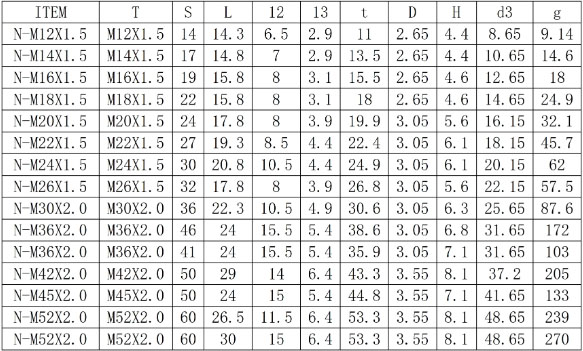

Specification: