Bronze Safety Valve

Typical Historical Applications:

• Steam boilers on locomotives and steamships

• Early industrial heating systems

• Compressed air systems

• Hot water heating systems

Overview

Bronze Safety Valves (Physical Components)

Purpose: A safety valve is a critical fail-safe device designed to automatically release pressure from a boiler, pressure vessel, or system when it exceeds a pre-set limit, preventing catastrophic failure.

Why Bronze Was Used:

• Corrosion Resistance: Excellent resistance to water, steam, and many chemicals, especially in marine environments.

• Machinability: Easy to cast and machine into precise shapes.

• Non-Sparking: Important in flammable environments.

• Durability: Good wear resistance and mechanical properties for many applications.

Modern Status:

• Largely Replaced: For high-pressure/temperature steam and critical industrial applications, materials like stainless steel, alloy steel, and chromium steel are now standard due to superior strength.

• Still Specified: Used in specific applications like:

◦ Marine low-pressure systems (sea water, cooling lines)

◦ Certain chemical processes where bronze is compatible

◦ Plumbing for potable water, gas, or oil lines (in pressure relief or regulator valves)

◦ Where non-sparking properties are required

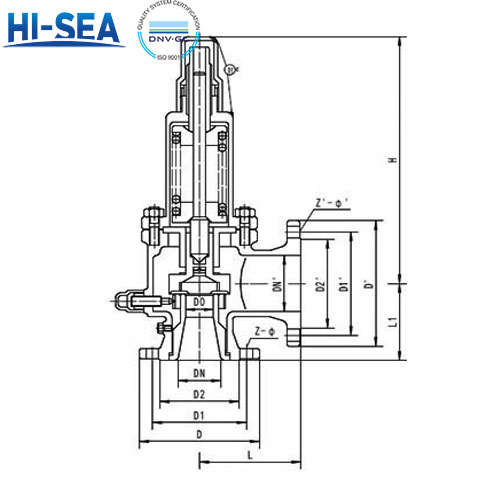

Drawing:

Picture: