Blanking Ends

Blanking Ends, as a special type of plug, has a specific application range. They are mainly used for hydraulic fluid connections and can withstand certain temperatures and pressures. Specifically, these plugs can withstand high temperatures of 120 ℃ and high pressures of 45Mpa, indicating that they are suitable for hydraulic systems that require a certain level of pressure and temperature.

Overview

Features:

1)Large force bearing area

2)Easy to fasten and disassemble

3)Can be used for buried processing

4)Suitable for narrow spaces

5)Provide better force transmission and anti slip performance

Installation:

1.Choose the appropriate plug: Based on the size and shape of the oil port, select the corresponding size and shape of the hexagonal oil port plug. For example, the DIN908 standard hexagonal cylindrical head throat plug is suitable for specific oil ports, ensuring that the nominal diameter of the plug matches the oil port.

2.Surface treatment: Plugs are usually left untreated or undergo specific surface treatments such as galvanizing to adapt to different usage environments and prevent corrosion and rust.

3.Installation method: Use an Allen wrench or other suitable tool to screw the plug into the oil port until it is completely sealed. For some applications, it may be necessary to use pressure to press the plug into the oil port to ensure that there is no gap between the plug and the oil port, achieving a complete sealing effect.

4.Material selection: Based on the usage environment and requirements, choose suitable materials such as carbon steel to ensure the durability and adaptability of the plug.

5.Safety inspection: After installation, a check should be conducted to ensure that the oil circuit is completely sealed and there are no leaks.

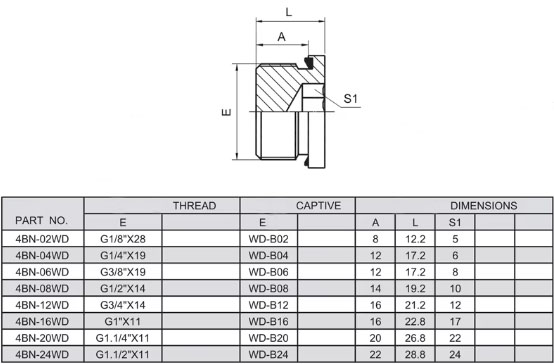

Parameters: