Ballast Water Treatment System

The pollution caused by the discharge of ship ballast water has been identified as one of the four major sources of pollution to the world's oceans. Ultraviolet (UV) disinfection has become one of the mature, reliable, and effective purely physical methods for disinfecting ship ballast water.

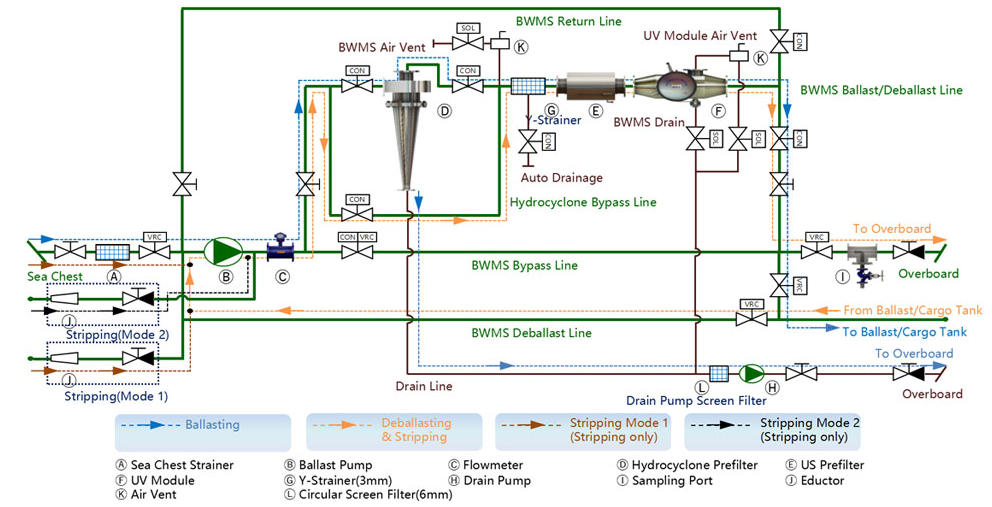

For this specific treatment object of ship ballast water, our expert team has designed a ballast water treatment system with the enhanced physical treatment technology (EPT) of hydrocyclone filtration + ultrasonic pretreatment + ultraviolet reactor disinfection as the core.

This system quickly treats the ballast water with powerful functions to complete the ballasting and discharge of the ship during the loading and unloading of cargo, and its discharge indicators fully meet the discharge standard requirements of the International Maritime Organization (IMO) and the United States Coast Guard (USCG).

The research and development, manufacturing, sales, and service of green, safe, efficient, and energy-saving marine environmental protection products is our aim. If you have related projects, please contact us.

Overview

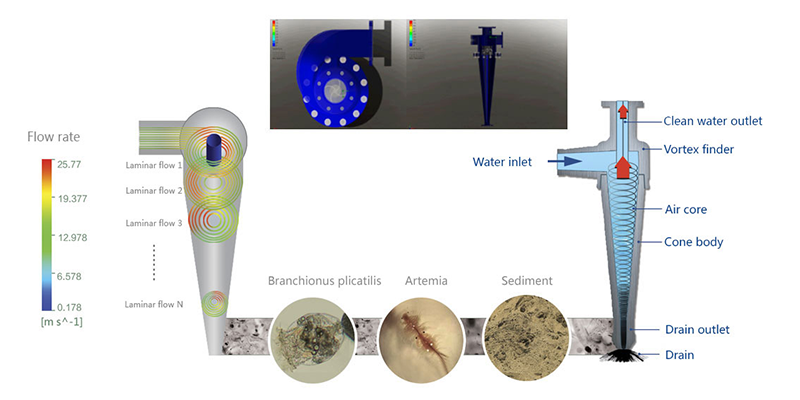

Revolutionary Breakthrough — Hydrocyclone Technology Replaces Traditional Filters

●No mesh ●No maintenance part ●Simple expansion

●Noiseless ●High-end duplex stainless steel ●Distributed installation

●No moving parts ●No service time limit ●Can be tilted for no more than 45 degrees to install

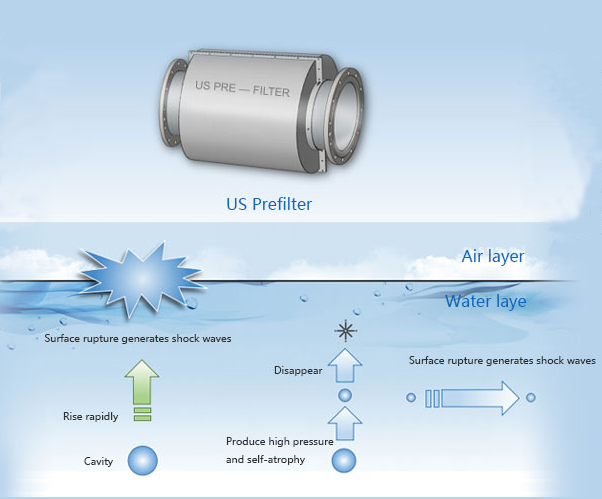

Ultrasonic Pretreatment Module

Ultrasonic Efficiency

The ultrasonic cavitation effect generates a high temperature of 1900 - 5200k and a high pressure of more than 500atm, with a temperature change rate of up to 109K/s, accompanied by a strong shock wave and a microjet at a speed of 110m/s. This extreme condition is conducive to the degradation of organic pollutants in the water body.

Suitable for a wider range of UVT, and is the best companion for ultraviolet sterilization

System Cleaning Function

Biological Cell Wall Breaking Efficiency

Targeted Special Design

The Parallel Field Theory Design Maximizes Efficiency

Duplex Stainless Steel Extends the Service Life of the Module

Customize Ultrasonic Vibrators and Generators Suitable for Marine Applications

The Lifetime of Cavitation Bubbles is Extremely Short and Harmless to the Environment and Human Body

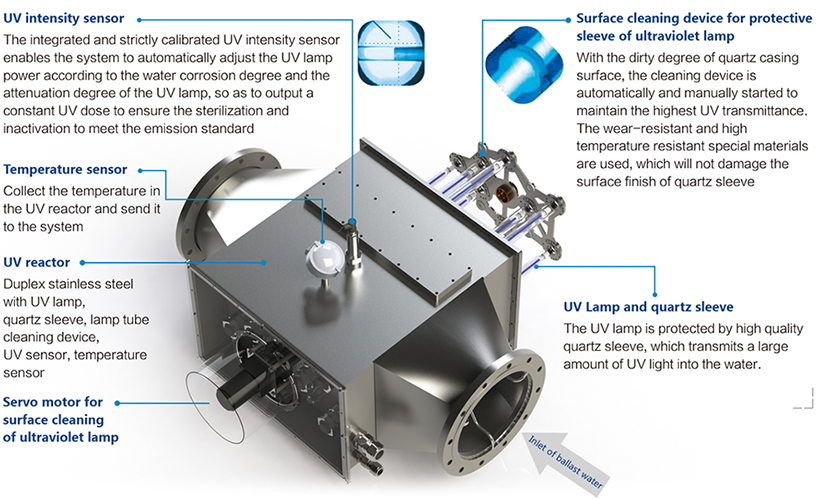

Ultraviolet Sterilization Module

Ultraviolet Reactor - Floating Fixed Value Tracking Technology, which does not affect the intensity of ultraviolet light with the change of water flow rate and turbidity, and maximizes the utilization of energy efficiency.

The medium-pressure ultraviolet lamp has a simple structure, a wide spectrum radiation range, and high intensity, making it a suitable ballast water treatment technology.

The working status of all lamps is monitored in real time, including: lamp number, ultraviolet dose, lamp running time, and it has functions such as ultraviolet output, maintenance, and alarm.

Control Device

Intelligent control, one-button start and stop

Ballast pump tracking and intelligent switching

Real-time monitoring of ultraviolet lamps and ultraviolet lamp cleaning devices

Color LCD touch screen, rich operating interface, freely switchable between Chinese and English

Real-time prompts for maintenance operations

All information is stored and saved for 5 years

Operating Principle Diagram

Update and Development

We have a group of scientific research teams with international standards specializing in ballast water treatment devices. We conduct system design through computer simulation (liquid flow pattern, light distribution, etc.) and conduct multiple biological tests to verify products that comply with the USCG test standards and the new IMO G8 standards. We professionally design high-efficiency ultraviolet disinfection and management systems, including UV power supplies and control systems.

By simulating every drop of water in the UV reactor (taking a grid composed of pixels with a diameter of 50 μm) to obtain consistent UV irradiation energy, our new generation of ultraviolet reactors has achieved up to 1.45 times the energy efficiency in terms of UV energy utilization compared to the old UV reactors in terms of its RED (Reduction Equivalent Dose). At the same time, this reactor has completed the type approval tests of USCG and IMO G8 code and obtained satisfactory results.

Project Examples

We have a total of 560 installations on ships distributed in China, Japan, Germany, Singapore, Turkey, Bangladesh, and other regions, including 272 new buildings and 288 retrofitted ships.

Solution for Retrofit on Operating Vessels

Certificate