Aluminum Anode for Ballast Water Tank

Aluminum anodes for ballast tanks are usually made of aluminum zinc indium (Al-Zn-In) alloy, which has excellent electrochemical properties and mechanical strength. The shape and size of aluminum anodes can be designed according to the specific application requirements, common cylindrical, flat and special-shaped anodes.

Overview

Advantages of Aluminum Anodes

High efficiency: The current efficiency of aluminum anode is high, and the current flow per unit weight is large.

Light weight: Compared with zinc anode, aluminum anode is lighter, which helps to reduce the load of the hull.

Long service life: aluminum anodes can work for a long time under appropriate conditions and do not need frequent replacement.

Environmental protection: aluminum anode is relatively environmentally friendly, less pollution to the environment.

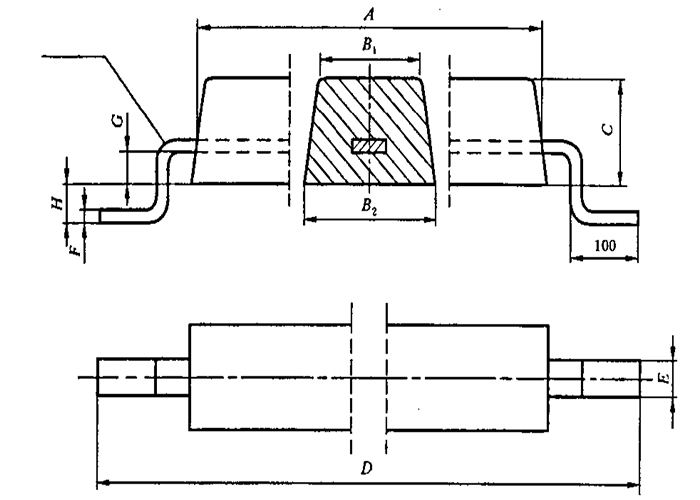

Drawing of Aluminum Anode for Ballast Water Tank

Main Specifications

Type | Specification | Size of Flat Iron | Net Weight | Gross Weight | ||||

A*(B₁+B₂)*C | D | E | F | G | H | |||

AT-1 | 500*(115+135)*130 | 800 | 50 | 6 | 40 | 60 | 20.5 | 23.0 |

AT-2 | 1500*(65+75)*70 | 1800 | - | Φ12 | 20 | 40 | 19.8 | 21.5 |

AT-3 | 500*(110+130)*120 | 800 | 50 | 6 | 40 | 60 | 18.0 | 20.0 |

AT-4 | 1000*(58.5+78.5)*68 | 1300 | - | Φ12 | 20 | 40 | 12.0 | 13.2 |

AT-5 | 800*(56+74)*65 | 1100 | - | Φ12 | 20 | 40 | 9.0 | 10.0 |

AT-6 | 1150*(48+54)*51 | 1450 | - | Φ12 | 15 | 35 | 7.6 | 9.0 |

AT-7 | 250*(80+100)*85 | 310 | 25 | 4 | 6~8 | 0 | 4.8 | 5.0 |

AT-8 | 200*(70+90)*70 | 260 | 25 | 4 | 6~8 | 0 | 2.8 | 3.0 |

Note: AT-7/AT-8 are flat type anode; AT-2/AT-4/AT-5/AT-6 are round steel flat iron anode | ||||||||