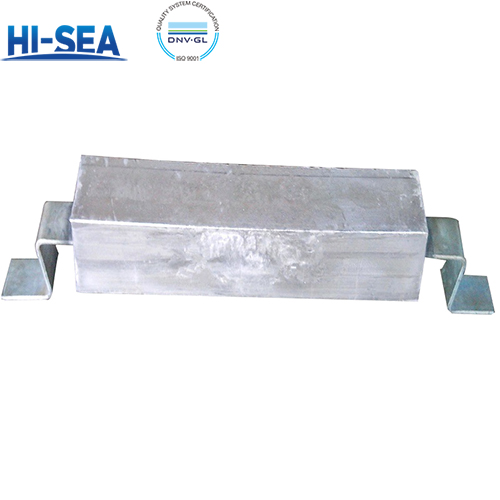

Aluminum Alloy Sacrificial Anode In Storage Tank

Aluminium anodes for storage tank deposition water anti-corrosion are suitable for all kinds of storage tanks, including those in different industries such as petrochemical, chemical, food and so on. Whether storing liquids or gases of different properties, aluminium anodes can provide reliable anti-corrosion protection for them.

Overview

Reasons for the use of Anodes in Storage Tanks

As the corrosion of the inner wall of the bottom of crude oil storage tanks and sewage tanks is mainly due to the electrochemical corrosion and bacterial corrosion caused by the crude oil deposition of sewage, and the crude oil deposition of sewage at the bottom of the tanks has a high salt content and high temperature, so its corrosive nature is strong. Sacrificial anode method is commonly used for cathodic protection of the tank bottom wall, this method is safe and reliable for storage tanks, no need for specialised management, and the protection effect is good.

The storage tank is a complex corrosive environment, where the activity of sulfate-reducing bacteria can significantly intensify localized corrosion (pitting). Sacrificial anodes inhibit both electrochemical corrosion and microbiologically influenced corrosion (MIC) by providing continuous cathodic current, which induces cathodic polarization on the tank bottom plate surface, lowering its potential below the corrosion potential. Aluminum anodes exhibit stable performance in this environment, making them a cost-effective and efficient choice.

Advantages

-Low cost: Compared with traditional anti-corrosion methods, aluminium anode costs less, which can greatly reduce the maintenance costs of storage tanks.

-Long-lasting: through the formation of oxide film layer, aluminium anode can remain effective for a long time, thus prolonging the service life of storage tanks.

-Environmental protection: aluminium anode material can be recycled, no pollution to the environment, in line with the requirements of sustainable development.

-Safety: the use of aluminium anode for tank deposition water anticorrosion is safe and reliable, no manual intervention is required, which reduces the operation risk.

How to Design an Anode System for Your Storage Tank?

Anode Selection:

Determine the required number, weight, and layout of anodes based on the tank diameter, medium composition (Cl⁻ concentration, SRB activity), and design life.

Installation Method:

Common installation methods include evenly distributing the anodes in the sediment water layer at the tank bottom or securing them with brackets. Ensure good electrical contact between the anodes and the tank bottom plate.

Monitoring and Maintenance:

Although the anode system is maintenance-free, it is recommended to inspect the remaining anode mass and measure the tank bottom plate potential during tank cleaning and maintenance to evaluate the protection effectiveness.

Applications Across Industries

Petrochemical Industry:

Crude oil storage tanks, refined oil tanks, and chemical raw material tanks.

Maritime and Port Operations:

Ship fuel tanks, ballast water tanks (though not strictly storage tanks, the principles apply similarly).

Power and Municipal Sectors:

Demineralized water tanks in power plants and sludge storage tanks in wastewater treatment plants.

Food Industry:

Certain food-grade storage tanks with corrosive media (material compatibility must be verified).

Picture of Aluminum Alloy Sacrificial Anode