52D Serial Dredging Cutter Teeth

The 52D serial dredging cutter teeth are specially designed for use in dredging applications to effectively cut through various types of materials such as sand, clay, and gravel. These cutter teeth are made from high-quality materials such as alloy steel to ensure durability and long-lasting performance in demanding dredging operations.

Various types of teeth like flare type, chisel type and pick type

Narrow chisel type are applied in packed sand and firm clay

Flare type are used for peat, sand and soft clay

Teeth with pick points are used for rock

Overview

The 52D serial dredging cutter teeth are a reliable and efficient solution for cutting through tough materials in dredging operations, providing a cost-effective and durable option for dredging contractors.

Features

Special mounting geometry

Wear Resistance: The teeth are designed to withstand wear and tear, ensuring they maintain their sharpness and cutting efficiency over time.

Easy Installation: The teeth are easy to install and replace, allowing for quick maintenance and minimizing downtime during dredging operations.

Versatile Application: The 38DS serial dredging cutter teeth are suitable for a wide range of dredging applications, including river dredging, harbor maintenance, and land reclamation projects.

Compatibility: The teeth are compatible with a variety of dredging cutter heads, making them a versatile and cost-effective choice for dredging operations.

Increased lifetime, decreased frequency and duration of maintenance.

Can be customized according to your requirements or can provide OEM services.

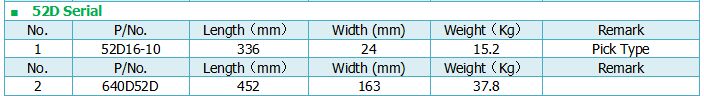

Technical parameters of 52D Serial Dredging Cutter Teeth