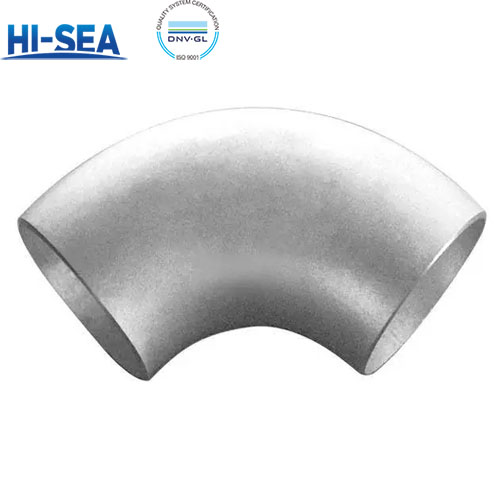

30 Degree Pipe Bend

30 degree ventilation pipe ducts are generally made of aluminum alloy, stainless steel and other materials, with strong corrosion resistance and long life. The pipe bend can change the direction and speed of airflow, turn the wind from one direction to another, and can slow down the flow rate, avoiding the direct impact of the wind direction, ensuring the stable operation of the system. At the same time, when passing through the elbow, the energy of the system flow will also be partially dissipated, thus reducing the system noise and improving the energy efficiency of the fan.

Overview

Design:

Pipe bend is usually made of galvanized sheet, ordinary carbon steel plate or stainless steel plate. It is necessary to choose the appropriate material according to the use of the environment and the requirements of the duct system. Factors such as stability, strength and corrosion resistance should be taken into account when selecting materials.

When making pipe bend, dimensional calculations need to be made to determine the cutting and bending requirements of the material. Specifically, parameters such as the radius, corner, angle and length of the elbow need to be determined.

Bending shape processing is a key step in the production of ventilation elbow. Specifically, with the help of pipe bender, roll forming machine and other equipment to bend the sheet material into a predetermined curve shape. In practice, for different materials and thicknesses, different process parameters need to be used to ensure the quality requirements of the elbow.

Picture: