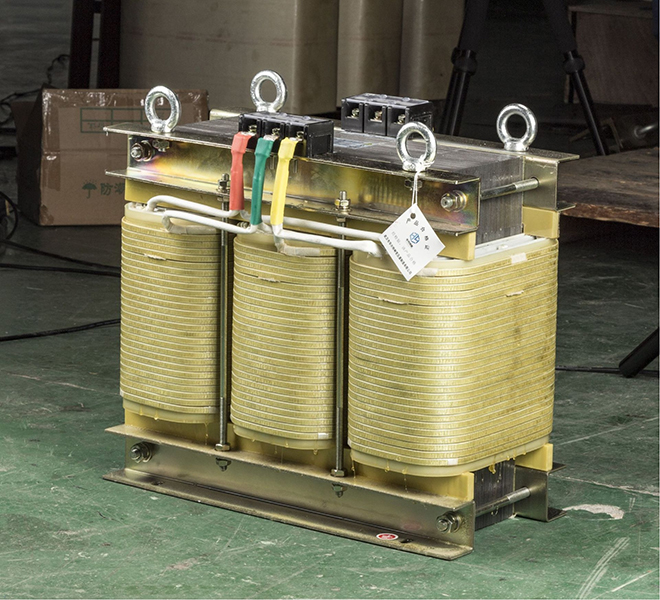

3-phase Dry-type Transformer

Our 3-phase dry-type transforms are mainly used for controlling power and power supply of various high and low voltage electrical equipment, import and export equipment, precision machine tools, UPS, electroplating, lighting, heating, communication, chemical industry and other industry equipment. It has the advantages of small size, light weight, simple maintenance and reliable operation.

Overview

Standard

Conform to the standards of B/T 9646-1999, GB 19212.5-2006, GB 1904.11-2007.

Technical & craft characteristics

The core is made of high-quality cold-rolled silicon steel sheets.

According to the insulation level, it is impregnated with insulating paint of the corresponding insulation level to effectively reduce noise, salt spray and mold.

The box is made of high-quality steel plates. The structure fully considers air circulation and can effectively play a protective role.

Convenient connection of wiring cables.

Voltage and current meters, power indicator lights, molded case circuit breakers, etc. can be installed on request.

Working condition

Altitude: ≤1000m

Ambient temperature: -10~+45℃

Relative humidity: ≤95% at 26℃

Environment: Indoor

Note: Please provide protection level when using outdoors

Technical parameters

Connection group: Y,yn0/ Y,d11/ D,yn11

Rated voltage: 690V, 660V, 440V, 380V, 220V

Rated frequency: 50Hz/60Hz

Capacity: 1kVA-2500kVA

Protection class: IP00,IP20

Insulation structure: Class B, Class F, Class H

Specification

Model | Capacity | No-load loss | Load loss | No-load current | Short-circuit impedanc | Size(mm) | Weight | Size of the hull(mm) | Gross weight | ||||

SG-3/0.5 | 3 | 80 | 115 | 14 | 3.5 | 240 | 130 | 230 | 36 | 400 | 260 | 380 | 50 |

SG-5/0.5 | 5 | 95 | 175 | 12 | 3.5 | 290 | 160 | 270 | 49 | 450 | 300 | 420 | 57 |

SG-7.5/0.5 | 7.5 | 130 | 250 | 11 | 3.5 | 330 | 250 | 300 | 65 | 490 | 360 | 460 | 73 |

SG-10/0.5 | 10 | 160 | 305 | 10 | 3.5 | 330 | 250 | 360 | 75 | 490 | 360 | 520 | 87 |

SG-16/0.5 | 16 | 200 | 395 | 9 | 3.5 | 400 | 236 | 390 | 106 | 560 | 380 | 560 | 125 |

SG-20/0.5 | 20 | 210 | 510 | 7 | 3.5 | 460 | 280 | 400 | 132 | 620 | 400 | 570 | 157 |

SG-25/0.5 | 25 | 230 | 560 | 6 | 3.5 | 440 | 300 | 420 | 153 | 600 | 430 | 590 | 183 |

SG-30/0.5 | 30 | 210 | 610 | 1.5 | 3.5 | 110 | 300 | 120 | 159 | 600 | 130 | 590 | 189 |

SG-35/0.5 | 35 | 250 | 680 | 4 | 3.5 | 530 | 320 | 420 | 197 | 690 | 460 | 590 | 235 |

SG-40/0.5 | 40 | 260 | 725 | 4 | 3.5 | 560 | 320 | 430 | 214 | 730 | 450 | 600 | 254 |

SG-50/0.5 | 50 | 275 | 1050 | 3.5 | 3.5 | 580 | 355 | 500 | 280 | 750 | 495 | 695 | 320 |

SG-63/0.5 | 63 | 290 | 1325 | 3 | 3.5 | 630 | 350 | 450 | 295 | 800 | 495 | 700 | 335 |

SG-80/0.5 | 80 | 380 | 1540 | 3 | 3.5 | 650 | 395 | 540 | 368 | 820 | 550 | 700 | 410 |

SG-100/0.5 | 100 | 460 | 1950 | 2.5 | 3.5 | 700 | 405 | 670 | 490 | 900 | 560 | 860 | 540 |

SG-125/0.5 | 125 | 560 | 2270 | 2.2 | 3.5 | 810 | 430 | 670 | 550 | 1000 | 600 | 860 | 610 |

SG-150/0.5 | 160 | 640 | 2440 | 1.8 | 3.5 | 825 | 430 | 690 | 590 | 1000 | 600 | 880 | 660 |

SG-200/0.5 | 200 | 760 | 2665 | 1.8 | 3.5 | 840 | 460 | 800 | 760 | 1010 | 610 | 940 | 840 |

SG-250/0.5 | 250 | 820 | 2915 | 1.8 | 3.5 | 855 | 500 | 800 | 830 | 1025 | 650 | 1030 | 910 |

SG-350/0.5 | 350 | 980 | 3930 | 1.5 | 4 | 1000 | 510 | 950 | 1030 | 1200 | 650 | 1150 | 1150 |

SG-400/0.5 | 400 | 1120 | 4210 | 1.5 | 4 | 1000 | 600 | 1000 | 1080 | 1300 | 750 | 1200 | 1200 |

SG-500/0.5 | 500 | 1320 | 5155 | 1.5 | 4 | 1100 | 650 | 1050 | 1350 | 1400 | 800 | 1250 | 1480 |

SG-630/0.5 | 630 | 1550 | 6205 | 1.5 | 6 | 1150 | 700 | 1100 | 1570 | 1500 | 850 | 1300 | 1730 |

SG-800/0.5 | 800 | 1800 | 6300 | 1.2 | 6 | 1250 | 750 | 1200 | 1810 | 1600 | 900 | 1400 | 1990 |

SG-1000/0.5 | 1000 | 2050 | 8590 | 1.2 | 6 | 1350 | 800 | 1300 | 2140 | 1700 | 950 | 1500 | 2350 |

SG-1250/0.5 | 1250 | 2350 | 10215 | 1.0 | 6 | 1450 | 850 | 1400 | 2650 | 1800 | 1000 | 1600 | 2910 |

SG-1600/0.5 | 1600 | 2800 | 12410 | 1.0 | 6 | 1550 | 950 | 1500 | 2890 | 1900 | 1100 | 1700 | 3180 |

SG-2000/0.5 | 2000 | 3800 | 15270 | 0.8 | 6 | 1650 | 1050 | 1600 | 3800 | 2000 | 1200 | 1800 | 4180 |

SG-2500/0.5 | 2500 | 4600 | 18135 | 0.8 | 6 | 1650 | 1150 | 1700 | 4450 | 2000 | 1300 | 1900 | 4900 |