2500m³ Ballast Water Management System

The nitrogen-charging and deoxygenating ballast water management system mainly includes the filtering unit, membrane separation unit, nitrogen generation device, and control unit. It adopts the treatment process of filtration + membrane separation + nitrogen-charging and deoxygenating to treat the ballast water. When ballasting, the filtering unit removes the organisms and solid particles larger than 50 microns in the ballast water and conducts automatic backwashing under the control of pressure difference or time, and the backwash water is directly discharged to the outboard; the membrane separation unit uses microfiltration membranes to remove solid particles and organisms, and conducts automatic backwashing under the control of pressure difference or time, and the backwash water is directly discharged to the outboard; nitrogen is injected into the ballast water before flowing into the ballast tank after passing through the membrane separation unit; when unloading, it is directly discharged to the outboard by the ballast pump. The discharged water quality meets the requirements of the IMO D-2 and USCG 46 CFR 162.060 standards.

We can provide you with a ballast water system with a treatment flow rate ranging from 200 cubic meters to 4000 cubic meters. In addition, we can also provide you with electro-chlorination and ultraviolet process ballast water systems. If you have the need, be sure to contact us!

Overview

Nitrogen BWMS Treatment Flow

Product Parameters

| TRC (m3/h) | Configuration power (kW) | Salinity | Water temperature | Ambient temperature | Compressed air pressure | Flow rate |

| 2500 | 29.7 | No limitation | No limitation | 0~55℃ | 0.7MPa | No limitation |

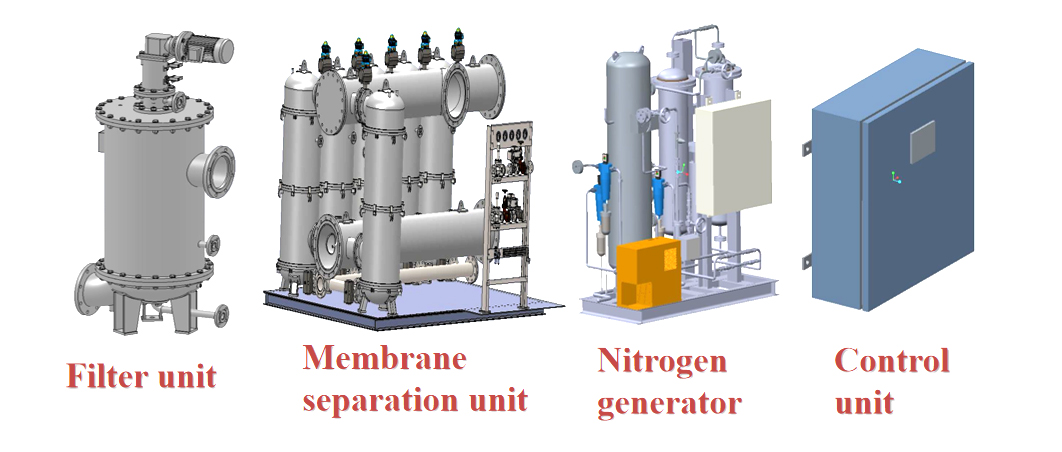

Product Composition

Filter Units

It is used to remove organisms and solid particles greater than 50μm, and carry out High pressure and suction back flushing of the filter core under differential pressure or timer.

Membrane Separation unit

It is used to remove organisms and solid particles greater than10μm, and performing gas-water mixture back flush on the membrane elements under the control of differential pressure or timer.

Nitrogen Generator

The nitrogen generator uses air as the material and uses molecular sieves to selectively adsorb nitrogen and oxygen.

Control Unit

It has Automatic and manual control system operation, used to monitor the operation status of the system and record system operation information.

Conclusion

For additional details, please contact us! For other types of products, please feel free to contact us, or visit our Ballast Water Management System homepage to learn more!