15PPM Bilge Water Separator

The 15ppm bilge water separator is a high-tech product in the field of marine environmental protection designed and developed in accordance with the resolution IMO.MEPC 107(49) of the International Maritime Organization, "Revised Guidelines and Technical Conditions for Anti-Pollution Equipment for Bilge Water from Machinery Spaces of Ships". It can effectively separate various types of fuel oil used in ships, including the mixture of highly dense residual residual oil and its emulsified oil, and the oil content of the effluent is <15ppm.

Contact email: <hs10@cqhisea.com>

Overview

Introduction

The 15ppm bilge water separator is a high-tech product in the field of marine environmental protection designed and developed in accordance with the resolution IMO.MEPC 107(49) of the International Maritime Organization, "Revised Guidelines and Technical Conditions for Anti-Pollution Equipment for Bilge Water from Machinery Spaces of Ships". It can effectively separate various types of fuel oil used by ships, including the mixture of highly dense residual residual oil and its emulsified oil, and the oil content of the effluent is <15ppm.

The 15ppm bilge water separator fully complies with:

GB3552-2018 "Emission Control Standards for Water Pollutants from Ships"

Article 14 of Annex I as Amended of IMO MARPOL 73/78 "International Convention for the Prevention of Pollution from Ships"

IMO MEPC. 107(49) "Revised Guidelines and Technical Conditions for Anti-Pollution Equipment for Bilge Water from Machinery Spaces of Ships" of the International Maritime Organization

Product Advantages

The design of the 15ppm bilge water separator not only pursues extremely high emission standards, but also considers more to meet the needs of shipowners and shipyards. Based on such a design concept, the advantages of the product are created:

High separation accuracy and processing efficiency, and the oil content in the discharged water is <15ppm;

Suitable for treating all oily pollutants from the bilge of the ship's machinery space, including various oil products that the ship may carry and their mixtures in the form of emulsions;

High degree of automation, simple operation, equipped with automatic oil discharge control, automatic temperature control and safety protection measures, no need for repeated flushing, and the service life is > 1 year;

Equipped with a 15ppm bilge water alarm device, which automatically displays the oil content of the discharged water, automatically alarms and returns to the bilge when the discharged water exceeds the standard, and automatically records;

The alarm device has the function of recording the date, time, alarm status and the operating status of the bilge water separator when alarming. The recording device stores records for at least 18 months and can display and print the report required for official inspection;

The product is small in size, light in weight, and simple in installation and maintenance;

Complete accessories and spare parts, and high-quality and efficient after-sales service.

Typical Technology | HBN Technology | Membrane Technology | General | Coalescence Technology |

Treatment effect of emulsified oil | Excellent | Good | General | Bad |

Filter life | > 1 year | 3-6months | About 6 months | <1 year |

System operation | Simple | Particularly complex | Simple | Simple |

Running costs | Low | High | High | Low |

Backwash | No backwashing | Frequent backwashing and chemical cleaning on a regular basis | Backwash regularly | No backwashing |

Volume | Small | Great | Large | Large |

Weight | Very light | Heavy | Heavier | Heavier |

Technical Specification Sheet

Model | Capacity m³/h | Pressure | Matching pump | Electric | Bilge water | Stability | Way of | ||

Normal MPa | Design MPa | Mobel | Power kW | Power kW | Configuration | Configuration | Configuration | ||

HBN-0. 1 | 0. 1 | 0. 03 | 0.3 | DZ-100 | 0. 12 | Optional | X0C-01 | Auto/Manual | Auto/Manual |

HBN-0. 25 | 0. 25 | 0. 03 | 0.3 | DZ-250 | 0. 18 | Optional | X0C-01 | Auto/Manual | Auto/Manual |

HBN-0. 5 | 0.5 | 0.03 | 0.3 | DZ-500 | 0. 25 | Optional | X0C-01 | Auto/Manual | Auto/Manual |

HBN-1.0 | 1.0 | 0. 07 | 0.3 | DZ-1000 | 0. 37 | 1.0 | X0C-01 | Auto/Manual | Auto/Manual |

HBN-2. 0 | 2.0 | 0. 07 | 0.3 | DZ-2000 | 0. 75 | 2.0 | X0C-01 | Auto/Manual | Auto/Manual |

HBN-3.0 | 3.0 | 0.07 | 0.3 | DZ-3000 | 1.1KW | 2.0 | XOC-01 | Auto/Manual | Auto/Manual

|

HBN-5.0 | 5.0 | 0.07 | 0.3 | DZ-5000 | 1.5KW | 3.0 | XOC-01 | Auto/Manual | Auto/Manual |

Recommended Capacity

Model | Capacity m3/h | Applicable Gross Tonnage of Ships(GT) | Remark |

HBN-0.1 | 0.1 | 400 | When selecting the oily water separator for the ship. |

HBN-0.25 | 0.25 | 550 | |

HBN-0.5 | 0.5 | 2500 | |

HBN-1.0 | 1.0 | 15000 | |

HBN-2.0 | 2.0 | 40000 | |

HBN-3.0 | 3.0 | 50000 | |

HBN-5.0 | 5.0 | Unlimited gross tonnage |

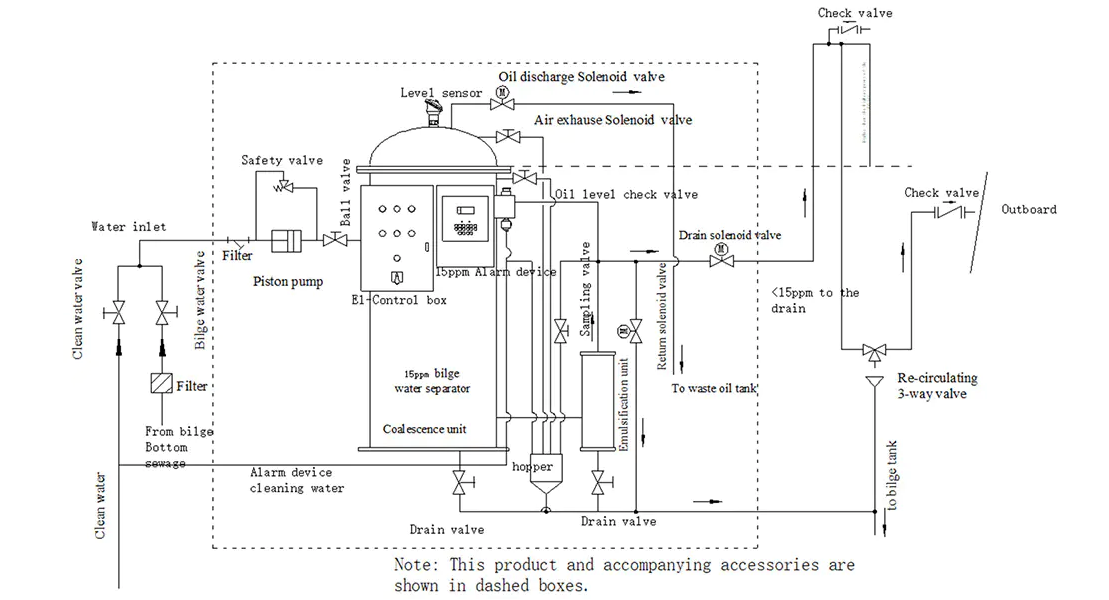

System Diagram

Conclusion

The 15ppm bilge water separator can effectively separate various types of fuel oil used by ships, including the mixture of highly dense residual residual oil and its emulsified oil, and the oil content of the effluent is <15ppm. It fully complies with IMO MEPC. 107(49) "Revised Guidelines and Technical Conditions for Anti-Pollution Equipment for Bilge Water from Machinery Spaces of Ships" of the International Maritime Organization.

If you have purchasing needs or questions in related aspects, you are welcome to visit our oily water separator homepage or contact us directly by email!